The New version of 3DCS integrated into SOLIDWORKS is coming soon! This webinar will showcase the product with a variety of modeling techniques and inputs. With multi-stage modeling as well as standard Moves, Tolerances, and Measures, there is something to see for both new users and experienced 3DCS modelers.

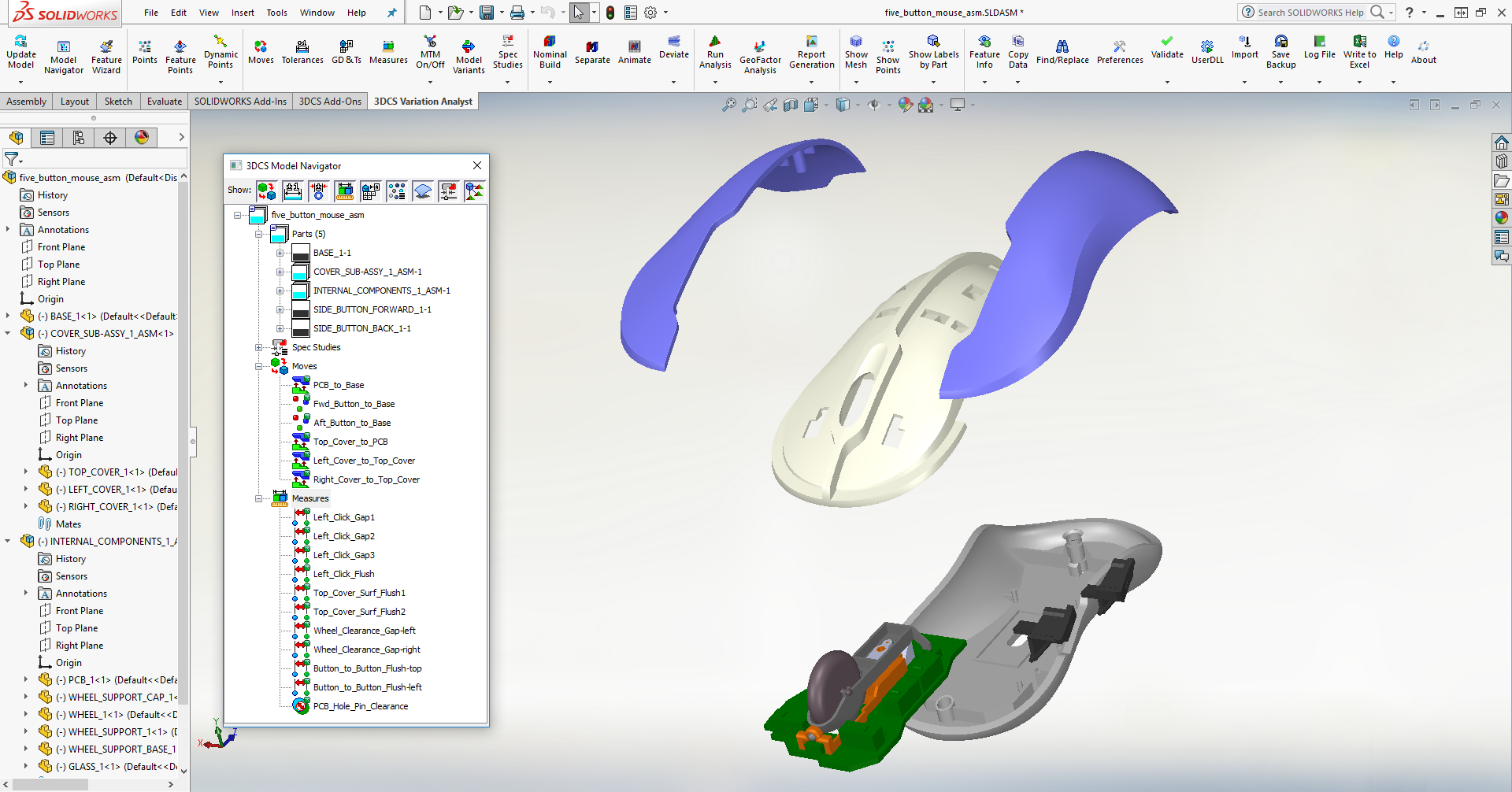

3DCS Variation Analyst for SOLIDWORKS is a fully integrated tolerance analysis software solution that simulates product assembly, manufacturing processes, and part tolerances in a 3D stack-up through three types of analysis: Monte Carlo Analysis, High-Low-Mean (Sensitivity) Analysis, and Geofactor (equation-based) Analysis.

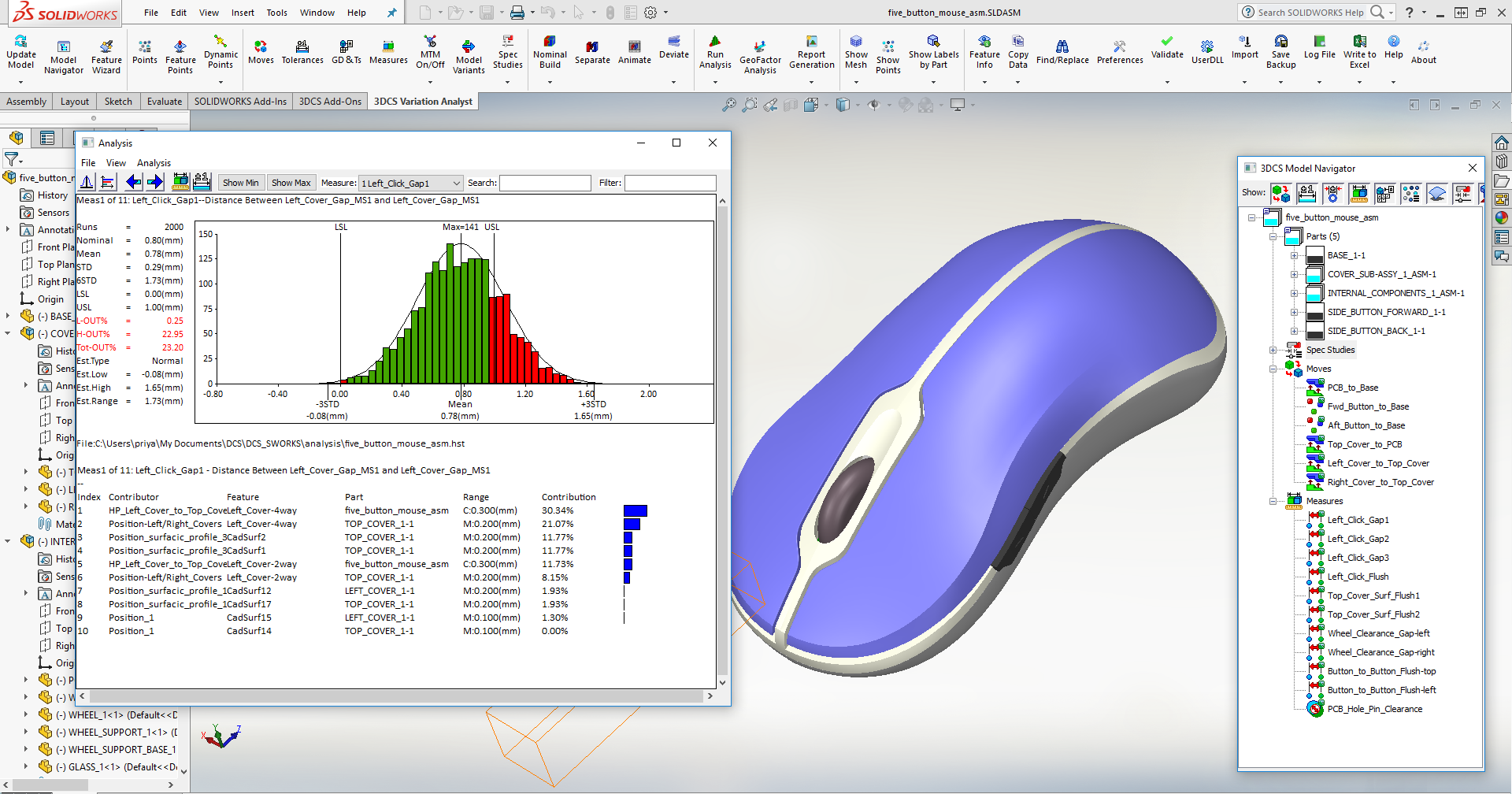

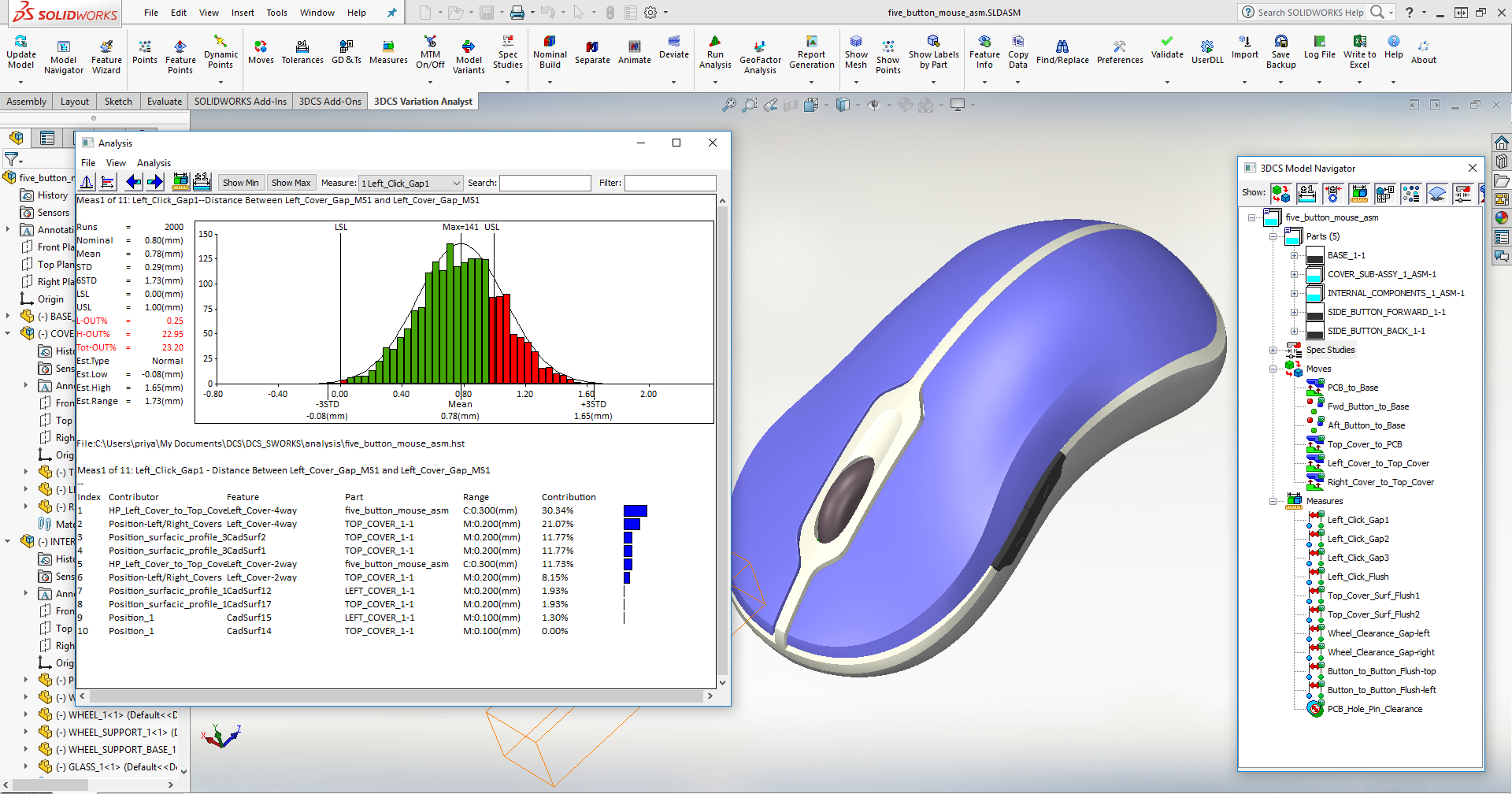

3DCS for SOLIDWORKS simulates part and process variation to give statistical outputs showing the estimated percent of products that will be out-of-spec, the primary contributing tolerances to variation as well as specified statistical metrics like cp, pp, cpk.

Integrated CAD tools provide a streamlined approach to analysis that improves adoption, training, and process implementation. With the ability to open 3DCS for SOLIDWORKS in the CAD platform, and utilize PMI and CAD characteristics, implementation of 3DCS as a tolerance analysis tool becomes easy to learn and apply. With an integrated modeling approach, 3DCS saves the analysis data in the model files, letting users manage their CAD model in leading PLM systems like Teamcenter, Windchill, Enovia, and 3DEXPERIENCE, automatically bringing their tolerance analysis data along with the CAD model. This answers the challenge of both file management and version control.

3DCS for SOLIDWORKS uses three methods of simulation; Monte Carlo Simulation, High-Low-Mean (Sensitivity analysis) and GeoFactor Analysis (Equation analysis). These together highlight the sources of variation as well as potential build issues in the product.

By accurately modeling the build process, users can determine how their process will affect the assembly in addition to their part tolerance stack-up. Combining part tolerance stacks and manufacturing and assembly processes creates a Digital Twin, a virtual prototype, that can be used to make decisions about design changes and tooling while reducing manufacturing variation that causes scrap and rework.

These Stories on 3DCS

No Comments Yet

Let us know what you think