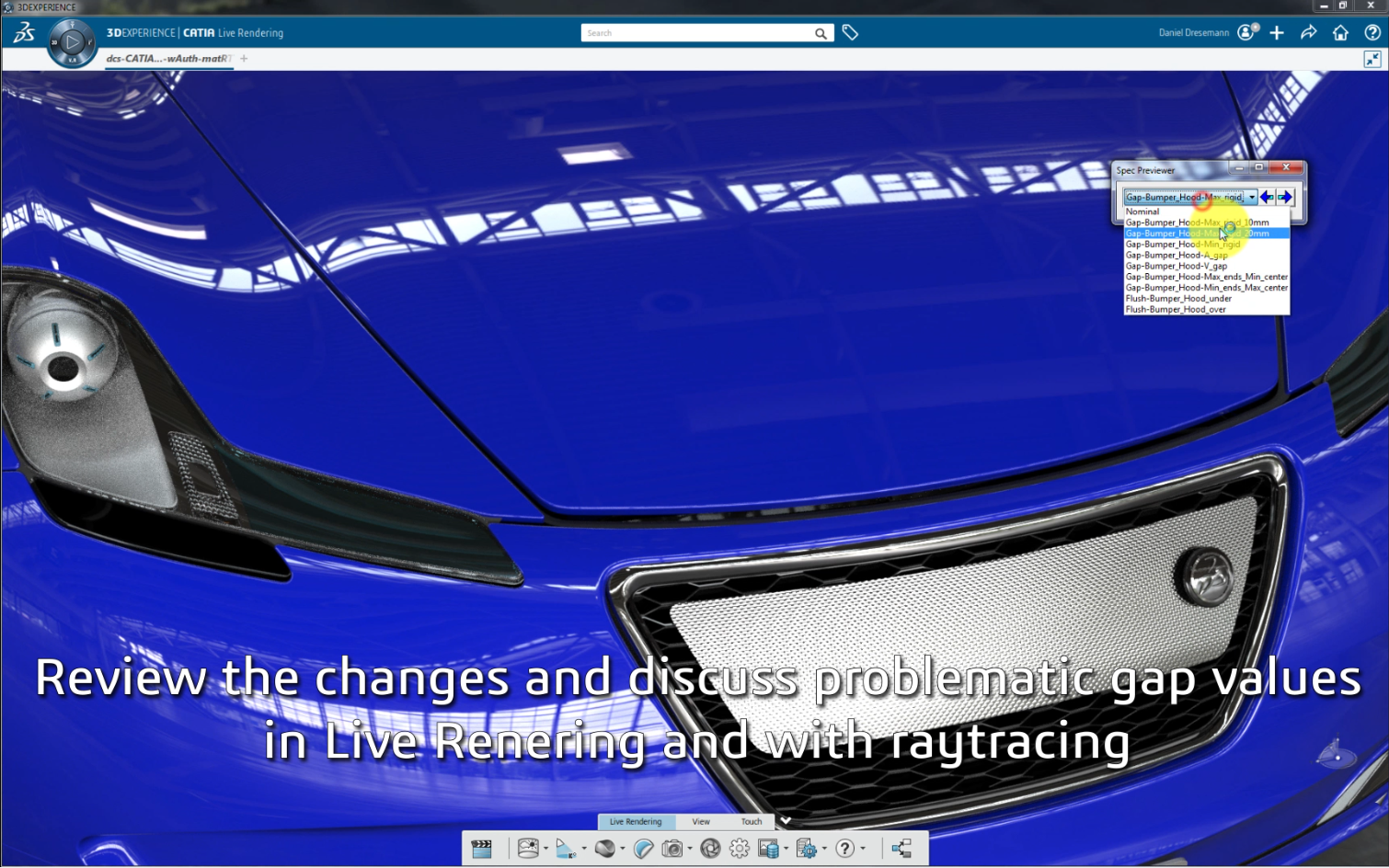

Using a combination of 3DCS tools and the 3DEXPERIENCE Platform Live Rendering, Dresemann will show how to create, use, and analyze Perceived Quality Studies.

As part of the DCS Global Technology Conference, Dresemann will demonstrate how to use Live Rendering in 3DEXPERIENCE and Virtual Reality systems along with 3DCS Spec Studies to display tolerance scenarios. He will show how to utilize the 3DEXPERIENCE Platform's Live Rendering to visualize gap and flush conditions in order to determine acceptable tolerance objectives.

Example of Daniel Dresemann working as part of a Design Collaboration with the 3DEXPERIENCE Platform

Comparing these design objectives to Spec Studies created from Tolerance Stack Up outputs, called Variation Studies, to see whether the objectives chosen by the design team can be met by the manufacturing engineer's specifications offers a medium for discussion between design and manufacturing.

Once compared, the two teams can collaborate using the model as a source of visualizing their points and outputs and come to a compromise on specifications and tolerances for a given design. Doing this early in the digital phase also gives engineers and designers more tools to work with, as making design changes before any tools are cut is as simple as a click of the mouse.

Daniel Dresemann will be presenting at the DCS GTC event on Tuesday, May 11th at 1:30 pm EST.

3DCS Variation Analyst for 3DEXPERIENCE is an integrated software solution in CATIA 3DEXPERIENCE that simulates product assembly and part tolerance 3D stack-ups through Monte Carlo Analysis and High-Low-Mean (Sensitivity) Analysis.

3DCS for 3DEXPERIENCE simulates part and process variation with Monte Carlo Simulation to give statistical outputs showing the estimated percent of products that will be out-of-spec, the primary contributing tolerances and parts to variation issues and specified statistical measures such cpk and ppk.

These Stories on CATIA

No Comments Yet

Let us know what you think