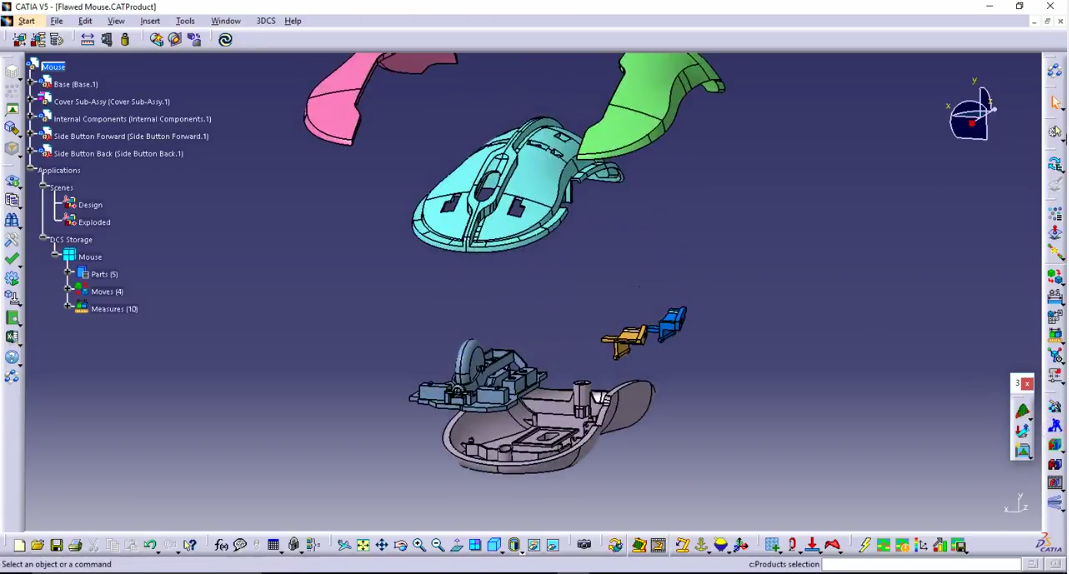

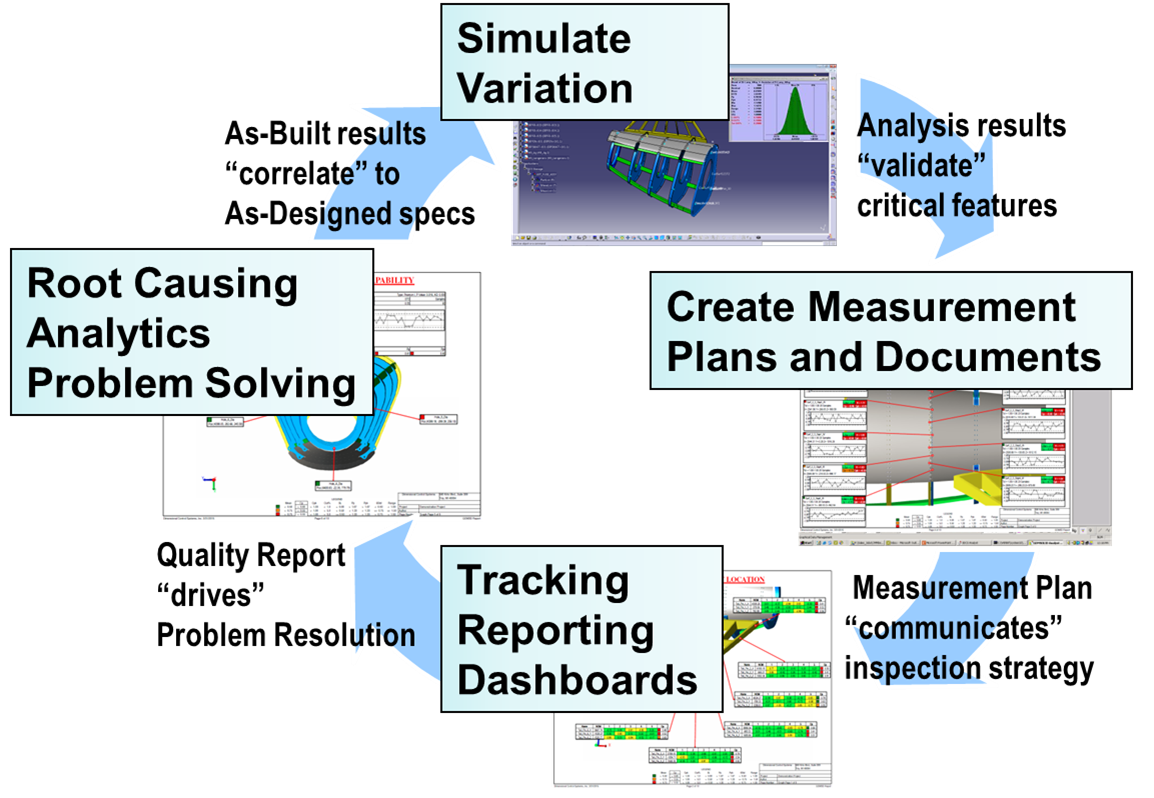

Quality 4.0 connects processes and tools, streamlining modeling creation and collaboration. See how tolerance analysis software validates and optimizes GD&T, simulating a digital twin and providing the risk of failure based on part tolerances and the assembly process. These simulations then feed downstream applications, creating SPC and manager reports and critical to quality features to direct measurement plans and manufacturing. The model continues to provide value by utilizing measured plant data to root cause production issues and testing solutions.

Join Gary Bell, ASME Certified Trainer, as he goes through the Closed Loop process from CAD embedded GD&T to final product problem solving.

Click Here to Register for this FREE Webinar

Click Here to Register for this FREE Webinar

3DCS Software and QDM Software are designed to communicate, effectively creating a complete quality system from cradle to grave of PLM. The purpose of a DCS Quality Solution is:

3DCS Software and QDM Software are designed to communicate, effectively creating a complete quality system from cradle to grave of PLM. The purpose of a DCS Quality Solution is:

Feed Back Loops - At each stage of the process, data can be fed back into the CAD model and 3DCS Software, using the measurement plan correlation to tie measurement and inspection data to CAD points. This lets users run new analyses with measurement data to validate the design, root cause issues and make design updates.

Reuse Your Data - At the end of the process, all of the data can be easily packaged and used as a basis for future projects, keeping you from having to repeat the same design changes.

These Stories on CATIA

No Comments Yet

Let us know what you think