CAD models are now ubiquitous with manufacturing. However, once the model is done, and converted to 2D prints, it is often forgotten. Why? It is hard to correlate plant data with the CAD model and continue to use it. This is why, when design is done, the model is often shelfed until needed for a future design product. With 3DCS Inspection Planner, creating inspection plans to correlate the data makes it easy to bring inspection and measurement data back into your CAD model to solve design problems and build issues.

Fully integrated in CATIA, both V5 and V6 3DEXPERIENCE, 3DCS Inspection Planner converts CATIA and 3DCS points into inspection coordinates for use by metrology teams, inspection labs and CMM's.

Fully integrated in CATIA, both V5 and V6 3DEXPERIENCE, 3DCS Inspection Planner converts CATIA and 3DCS points into inspection coordinates for use by metrology teams, inspection labs and CMM's.

The tool is easy to use, and works like any other 3DCS Add-on module, being activated from the CATIA drop down. Let me show you.

How Does Inspection Planner Work?

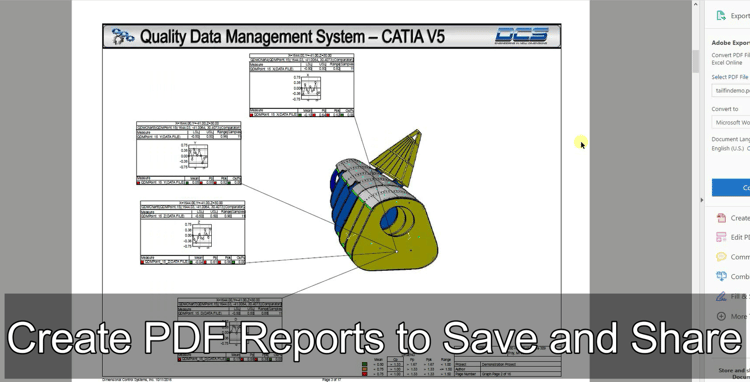

Start with your CAD model. Select your points and activate Inspection Planner. This brings up the template view, where you can modify the views for the inspection plan pages, where the inspection and measurement information will be displayed, how it will be displayed, and what information to include. Essentially, you are creating an Inspection Plan Template for use with that product that can be used repeatedly by the shop floor to inspect the parts, and then view the results with SPC metrics and call outs.

I'm glad you asked. There are a couple of ways having CAD based inspection plans can be of help to you and your team.

Make sure the points and places you find in the model that are sensitive to variation and critical to your quality are the same points being measured on the plant floor. With these points correlated, it becomes easy to bring that measurement data into the model, replacing tolerance ranges with actual measurements and allowing Monte Carlo simulations to test the product and through iterative design changes help resolve build and assembly issues.

As you are monitoring the key control characteristics of your product, it is important to constantly monitor the quality of those points. Through use of the Inspection Template, plant managers and professionals can instantly see the quality metrics of the points they are inspecting and collaborate with engineering about any issues.

Utilizing a web based or PLM system, the Inspection Template can be converted into a report to upload into a PLM or SPC system to monitor the quality or feed dashboards and reporting. Feed downstream applications to monitor your plant quality and in turn your product quality.

With a familiar interface to CATIA users, 3DCS Inspection Planner makes it easy for designers and engineers to quickly create inspection plans and templates while developing their models. This makes the entire process smooth and easy, with little to no training required.

Well, here is a short video to give you an idea:

Interested in a demo or trying it out for yourself?

Contact DCS to learn more!

These Stories on CATIA

No Comments Yet

Let us know what you think