When: November 19th

When: November 19th*Gotowebinar requires the download of a small client, please make sure to check with your IT to see if you can install the client.

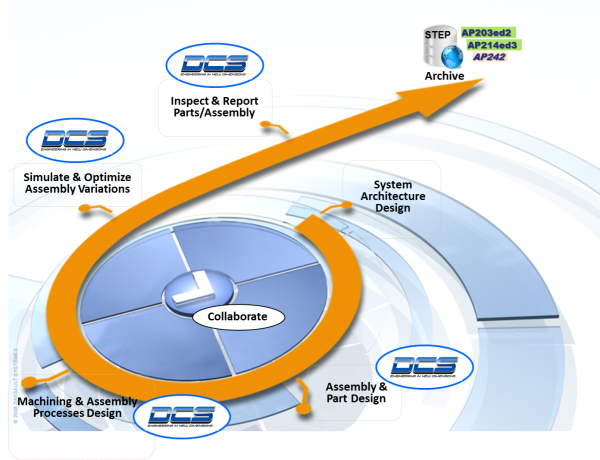

Join DCS for this free webinar event and learn how to analyze product variation with all of V6's powerful tools. The entire 3DCS suite is available, allowing the user to model rigid and compliant parts, thermal effects, bending and flexing, clamping, mechanical and kinematic assemblies, as well as quickly optimize designs for cost and quality.

Analyze all these aspects taking into account both part and process variation.

In addition, V6's powerful live rendering allows for high end visualizations, letting the user model their variation and see its affects on the final assembly's appearance.

Add your GD&T through V6's Functional Tolerance & Annotation's

Utilize 3DCS to do more than validation. Optimize designs early on in the product lifecycle, design assembly and parts using DFMA (Design for Manufacturing and Assembly) while simulating assembly processes and part relationships. Optimize or eliminate tooling and setup locator schemes and measurement plans.

All of this without leaving the V6 Environmnet.

Come join DCS on Tuesday, November 19th to see how 3DCS can be used to optimize and improve your product quality.

Can't make the live event? Register to receive the recording shortly after the live broadcast.

These Stories on CATIA

No Comments Yet

Let us know what you think