In Steven Covey's 7 Habits of Highly Effective People, he talks about starting with the end in mind. When using engineering, this is using the Scientific Method. If I had to pick the greatest tool in my tool box, I'd have to pick the Scientific Method.

Now, you're all familiar with the Scientific Method:

Observe - from observation you form some Hypothesis on whether it could be this, or it could be that (in regards to an engineering or manufacturing issue).

I don't act on those hypotheses unless I've tested them and found some clever way that I can quickly and determine if my hypothesis is true or false.

I gather Data based on the tests or information and create some conclusions.

And then, I can repeat as needed. If the hypothesis is confirmed, what does that mean? Where do we go next?

If it passes, We can have some new hypotheses, new tests, new conclusions.

If its proven false, what can we do next?

Remember what I said in the last habit, these are all related. If I find out that the hypothesis is false, what am I going to do next; fail fast. This is one of things that allows you to go fast is using the scientific method.

So is this some fancy thing? When did I learn this?

I think most of us learned this in junior high, high school, or early college. It isn't advanced knowledge or math. It is pretty basic.

Unfortunately as I've observed, most people seem to have forgotten about it. They don't use it. Then they are often wondering how come we aren't moving forward as fast as we want? Well, they've forgotten the basics, and the scientific method is one of the basics that has served me well over and over again in my career across many jobs.

You know, working without a hypothesis is slow and wasteful. You have all these people talking or acting without a hypothesis, and it becomes a bit of a struggle.

One of my many jobs, is that I was pretty good at problem solving and I've launched many a vehicle. I've either been on the launch team or sent to the plant after launch as they struggle with quality issues.

At almost every launch I would meet these people who sit out in their trailer, and meet these engineers who were sent out of town, put up with a desk in a trailer or temporary housing, spending all day pouring through the numbers. They spent every day just looking at numbers and looking at numbers.

Every launch I would go over and introduce myself and ask, "what are you doing?"

The answer was of course, "Well, I'm looking. I have this problem, and I'm looking for an anomaly in the data."

"Okay, what is an anomaly? What is your hypothesis about what an anomaly is?"

Almost always, their hypothesis was, "I'm looking for something out of specification, because if everything is in spec, then the vehicle would be in spec. An anomaly is something that is out of spec."

Is that a fact? Well, it sounds plausible, but let's test. So I'd say, "Go find an out of spec situation that you think is going to cause the issue, and we'll take some data and have a look."

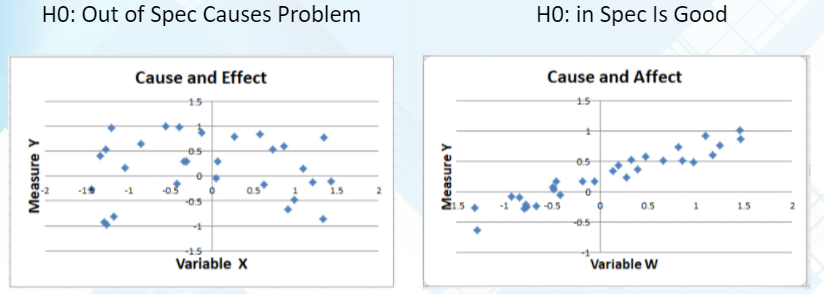

So this is typically would I find,

The X axis is the internal variable measurement we'd make on an in-process part that is out of spec, the Y axis is the measurement that we're trying to control, reduce variation, or shift the mean.

I would grab their data and measure the vehicles that I had the data on; measuring the output and plotting it. Is there a relationship between X and Y?

I don't think so. The data doesn't line up, and there clearly is no correlation (first chart - H0: Out of Spec Causes Problem). I think this hypothesis is proven to be false.

This really caused a lot of consternation and concern with people. It stood in stark contrast against their expectations.

Well, let's find out what is causal. So we'd look for other variables and the relationship between X and Y. About 80% of the variation in Y can be explained by variation in X. So the variation in Y is caused by something with X, so we have to do something with X.

Their issue occurs when the product is in spec!

They're holding onto their false hypothesis that in-spec is always good, and out of spec is always bad. This is a hypothesis that needs to be tested. It sounds plausible, but it needs to be tested.

That is a hypothesis that has been busted so many times.

The scientific method can be as simple as just recognizing what is a hypothesis and what is not. Once we have a hypothesis, we should test. So we should be very specific about what our hypothesis is, and get data on whether our hypothesis is true or false.

This allows you to get the right data at the right time to move really quickly through things. It's really simple; Ready, Aim, Fire, and not Ready, Fire. The Aim action is testing your hypothesis.

To see this done really well and a demonstration of the scientific method, I recommend you go watch Mythbusters. Go be a mythbuster. It's a great show where they test urban myths, folklore, and other commonly held beliefs.

It really teaches young people, non-scientists, non-engineers what the scientific method is. Go watch it, be a mythbuster. Although I must admit that whether they confirm or don't confirm the myth, there is always an explosion at the end!

(I don't recommend you cause any explosions, but it is very entertaining!)

Download the eBook below to get all 8 habits in one pdf

These Stories on T&T

No Comments Yet

Let us know what you think