Advanced Manufacturing Solutions. Building the Future NOW.

Increase efficiency. Reduce lead times. Improve margins. Attend THE BIG M and connect with the people, technologies, and solutions you need to accelerate your business and stay ahead of the competition.

__________________________________________________________________________

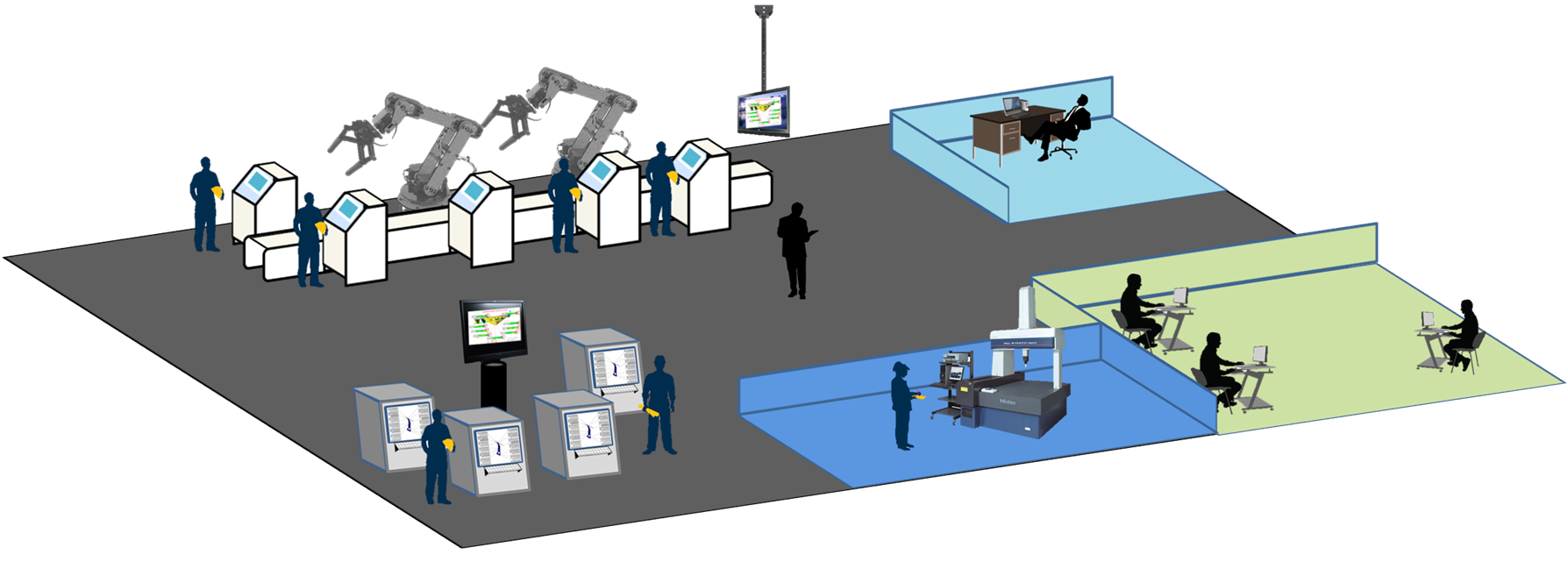

QDM is a modular system that can be implemented at three distinct levels in an organization. The system can be scaled with additional modules as the organization’s need grows.

At the basic level, QDM Analyst provides translators for mining and producing quality reports utilizing CAD graphics. This graphical reporting puts the information into decision making context, giving engineers and manufacturing professionals the ability to quickly understand production issues and the means to solve them.

At the plant level, QDM Plant Based System builds upon QDM Analyst to interconnect the manufacturing lines. The system allows for a graphical user interface at the shop floor data collection points to capture part by part inspection data entry, and automates the data processing of any inline or CMM results. This gives plant managers the ability to set up real time stations with graphics, giving the plant floor second by second understanding of product quality, while also providing QDM Analyst based reports and metrics. Utilizing the QDM System’s web based drill downs and root causing analytics lets Quality Managers dive deep into their data and find the information they need for continuous quality improvement and to validate lean manufacturing processes. In addition, with a few clicks, professionals can create reports from any set of data to see how specific machines, locations or shifts are performing, or to drill down into issues to identify problems.

At the plant level, QDM Plant Based System builds upon QDM Analyst to interconnect the manufacturing lines. The system allows for a graphical user interface at the shop floor data collection points to capture part by part inspection data entry, and automates the data processing of any inline or CMM results. This gives plant managers the ability to set up real time stations with graphics, giving the plant floor second by second understanding of product quality, while also providing QDM Analyst based reports and metrics. Utilizing the QDM System’s web based drill downs and root causing analytics lets Quality Managers dive deep into their data and find the information they need for continuous quality improvement and to validate lean manufacturing processes. In addition, with a few clicks, professionals can create reports from any set of data to see how specific machines, locations or shifts are performing, or to drill down into issues to identify problems.

Connecting plants together forms the Enterprise Level of QDM Systems. This level leverages multiple QDM Plant Based Systems with a web based method of interfacing the manufacturing information across multiple plants and global locations. Through the QDM WEB module, executives, plant managers, and engineers can all monitor product quality through dashboards that track inspection data analytics at the part, assembly, plant and enterprise level.

The latest version of the QDM System makes interconnecting an organization easy, and provides the means of connecting engineering and manufacturing through feedback loops throughout the product life cycle. The system allows different levels of users to mine for any shop floor data and create decision making reports with a few button clicks. This communication utilizes quality information as the standard language, helping engineers continually improve the product design while empowering manufacturing to identify the source of problems to quickly fix and resolve them. By implementing a QDM System within current processes and systems, companies can leverage the cost reductions in scrap and rework without changing their standard processes and current systems.

The latest version of the QDM System makes interconnecting an organization easy, and provides the means of connecting engineering and manufacturing through feedback loops throughout the product life cycle. The system allows different levels of users to mine for any shop floor data and create decision making reports with a few button clicks. This communication utilizes quality information as the standard language, helping engineers continually improve the product design while empowering manufacturing to identify the source of problems to quickly fix and resolve them. By implementing a QDM System within current processes and systems, companies can leverage the cost reductions in scrap and rework without changing their standard processes and current systems.

Through the use of QDM, major manufacturers across the world are gaining clear insight into their production, identifying and solving issues faster and more efficiently while improving process comprehension across the organization.

Join DCS at booth 334 at this year’s Big M Convergence conference to find out if QDM can help your organization increase insight into its manufacturing quality. Need passes? DCS has free passes to the event (a $75 value). Just Contact Us to get the code by phone or email.

Learn more about DCS's plant solution by joining the free webinar shortly before the event on May 28th, 2015. The webinar will walk through a virtual plant floor, highlighting how QDM modules can be interconnected to form a complete system.

- Benjamin Reese

DCS Marketing

These Stories on SPC

No Comments Yet

Let us know what you think