The QIF Standard is best thought of as a container. It holds a group of data together, providing unique identifiers for each feature and characteristic. This makes moving the data from team to team within an organization and into the supply chain much easier, as all the relevant data is present in one location, and the characteristics can be properly identified and communicated between people and machines by using the QPId (QIF Persistent Identifier) numbers to remove ambiguity. This allows a clean workflow of information downstream, while connecting all components of the digital thread. The enterprise gains trace-ability and transparency into their own workflow through versioning with QPId's.

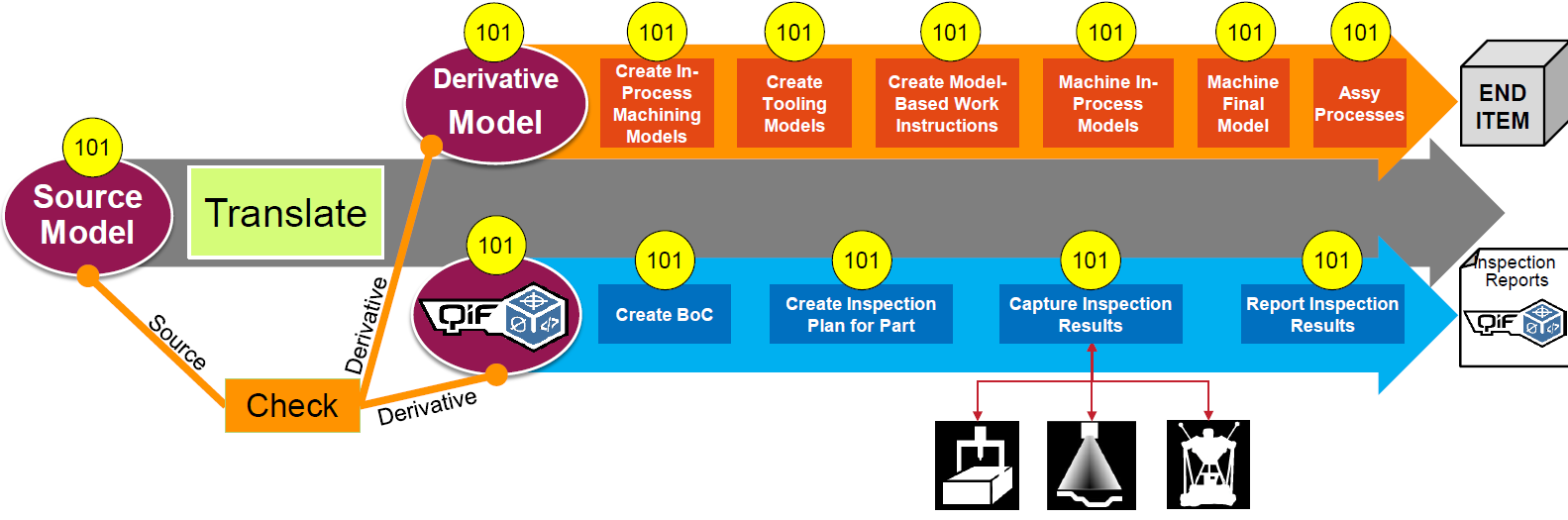

The QIF Standard connects all of the different operations (image courtesy Action Engineering)

QIF is an American National Standard supporting Digital Thread concepts in engineering applications ranging from product design through manufacturing to quality inspection. Based on the XML Standard, it contains a Library of XML Schema ensuring both data integrity and data interoperability in Model Based Enterprise implementation. DMSC is responsible for the oversight and maintenance of this standard.

The latest 3.0 version is an American National Standards Institute (ANSI) standard and was submitted and achieved ISO/TC184/SC4 fast-track approval.

One of the key functions in QIF is measurement rule types and XML schema, i.e., QIF Rules. These rules provide industry with a standard way of representing and sharing dimensional measurement strategy and resources selection rules in a supplier network employing various CAD software platforms. For example, an OEM can specify what type of coordinate measuring machine, probes, and probe tips can be used based on the tightest tolerance, smallest internal feature size, longest internal feature size, feature orientations in a setup, the part bounding box sizes in X, Y, and Z, and measurement requirements.

--- https://qifstandards.org/dmsc-announces-qif-3-0-release/

Using XML Technology, the QIF links CAD, characteristics, measurement data together to provide the full picture to engineers. (image courtesy Action Engineering)

QIF becomes the core component of Model Based Definition. It links the information needed, as in the modern world, one model will not suffice. Engineers need access to drawings, bill of materials, specifications, and measurement data.

In a model based world, it is not the goal to shove everything into a single data package. Everything doesn't need to be one single file. There will be need for a data package that can provide each group; design, manufacturing, quality, and supply chain, with the information they need to complete their work. Model Based Definition defines the process of sharing and using the information, while QIF provides the tool to track, manage, share, and protect the data as it moves through the process.

DCS and Action Engineering are collaborating to provide GD&&T and Model Based Definition training in August.

DCS and Action Engineering are collaborating to provide GD&&T and Model Based Definition training in August.

This open class is available to all interested parties, and will provide a strong foundation of GD&T with the intent to use it in a digital environment, such as converting 2D drawings to 3D CAD, or utilizing CAD based GD&T in the form of PMI or FTA. Sign up now to reserve your seat!

Learn more:

https://qifstandards.org/dmsc-announces-qif-3-0-release/

These Stories on CATIA

No Comments Yet

Let us know what you think