Modeling a Variation Analysis CAD Model creates a digital twin of your product. This virtual prototype behaves like your product, and can be used to simulate different builds of your product; essentially creating a digital assembly line and seeing all of the products made and how much variation each product has.

Using Monte Carlo Simulation, 3DCS simulates each tolerance within its range, normally weighted towards a standard distribution. The software also incorporates the manufacturing and assembly processes. These often include tooling, assembly sequence, force, and other variables. This combined variation changes the dimensions of each part for each build. In order to determine what those dimensions and tolerance stack up results are, you add virtual measurements onto your product.

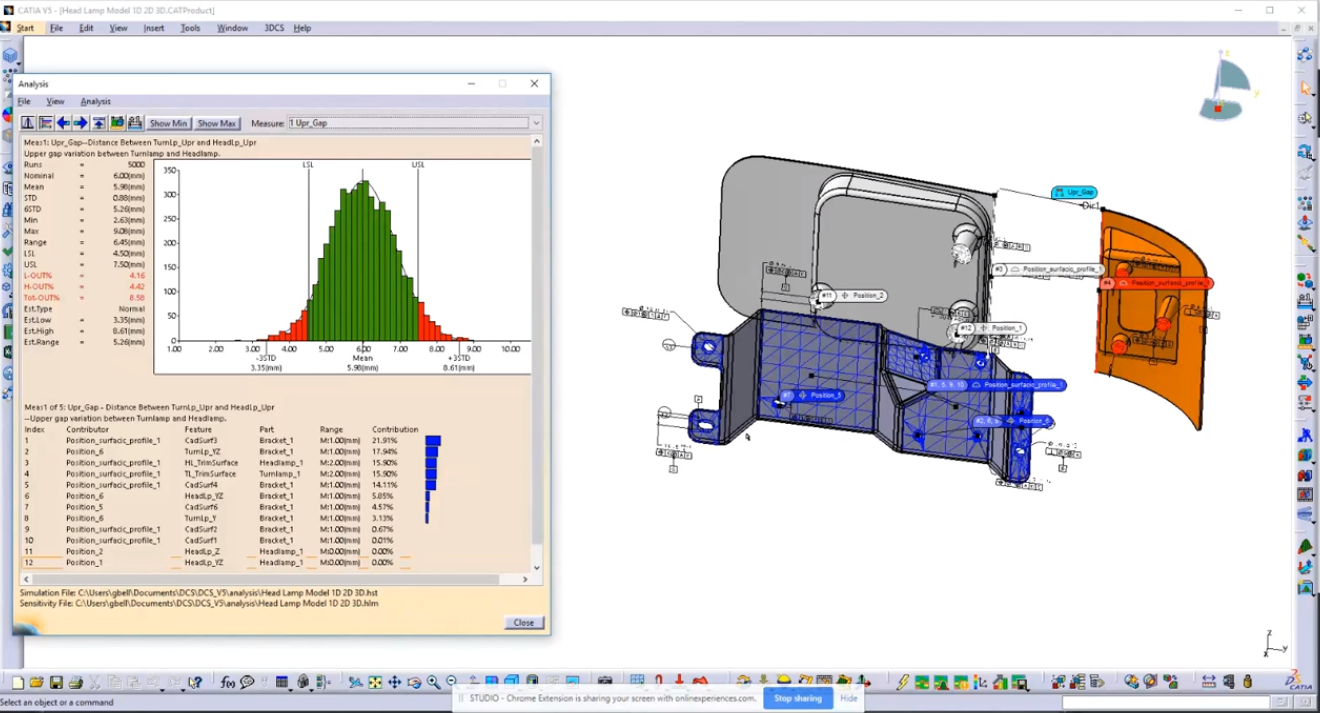

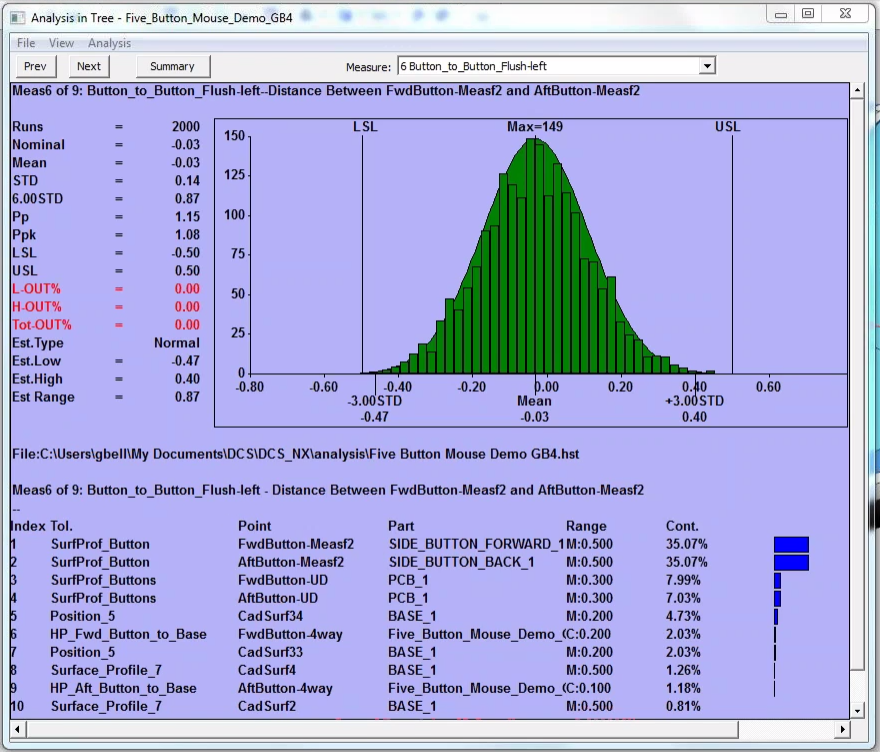

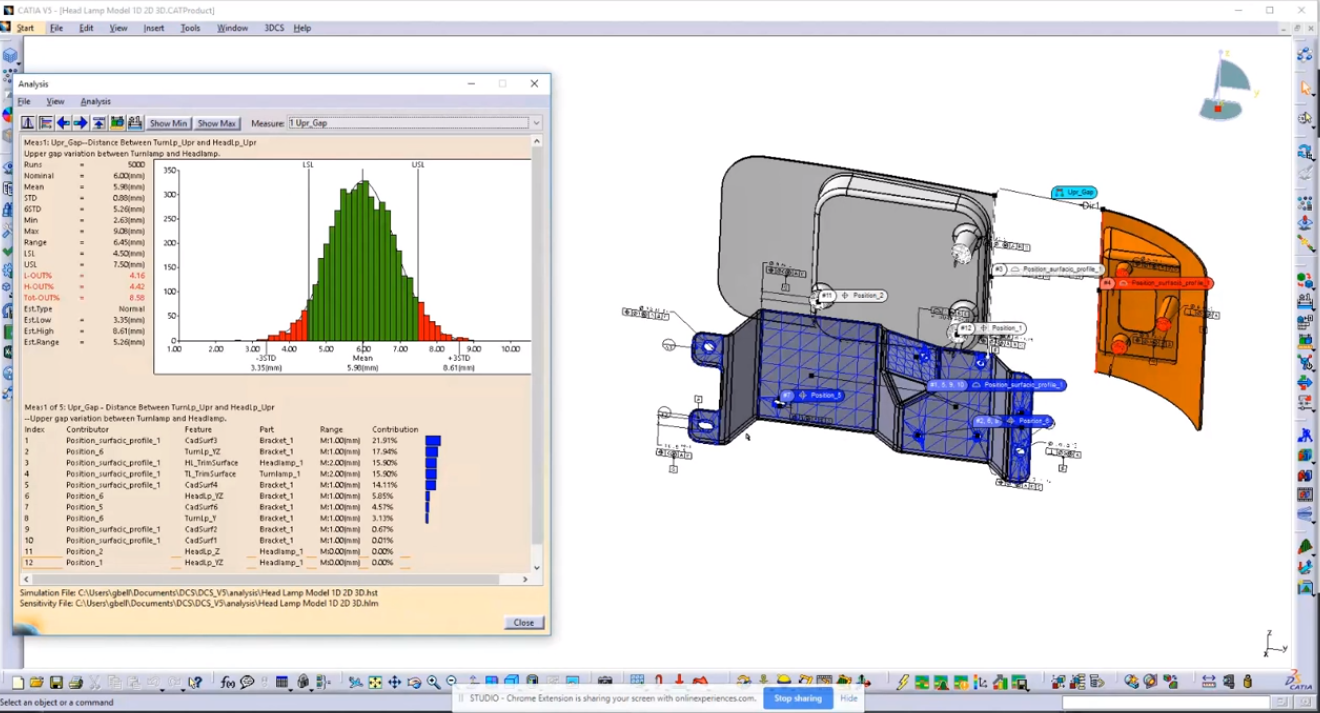

Each Measurement on your model gives you a complete statistical output

Each Measurement on your model gives you a complete statistical output

Measurements are what give you your outputs in 3DCS. These measurements can be used to simulate the real methods of inspection; how a FARO arm will measure the parts, or a check gage or fixture, or can be simple point to point measurements to give you the final value (as seen below in the gap highlighted in blue).

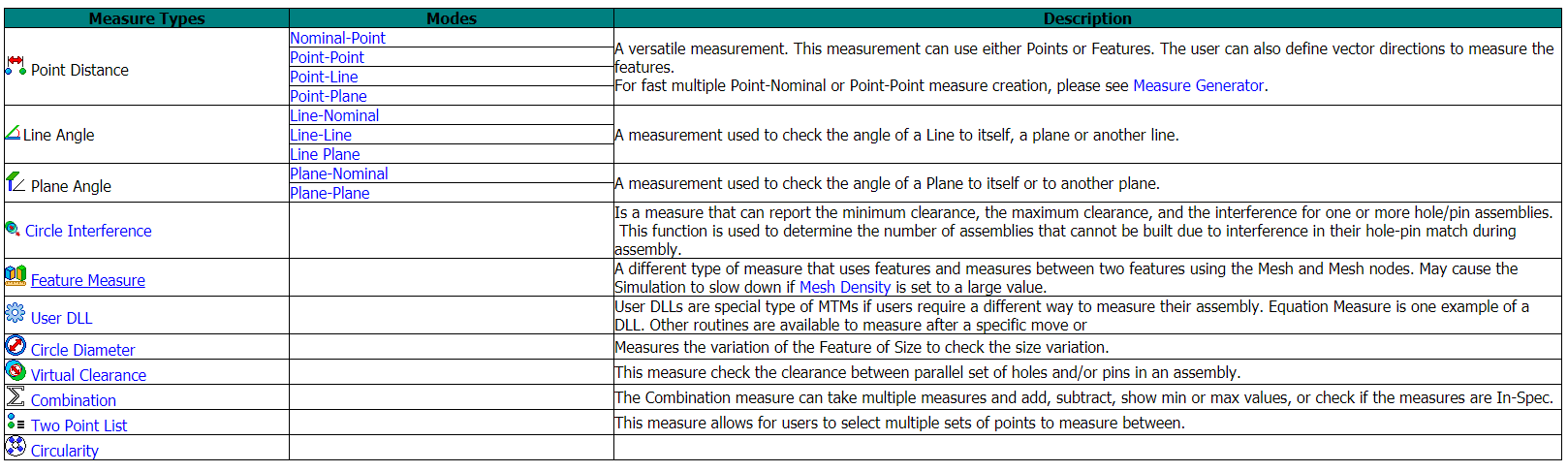

Sometimes, users need to know more than gaps or a flush condition. You may need to know whether a certain pair of points make contact or not in each build, or whether two parts are colliding. Many times, uses need to know the circumference or diameter of a hole or a combination of different measures (such as from a series of holes). All these conditions can be simulated in 3DCS using different Measurement types.

Some of the more complex Measurements require a custom measurement. Users can take advantage of the Equation Measure to create unique and custom Measurement scenarios. You can watch the webinar on Equation Measure by clicking below:

View the webinar on Equation Measure On-Demand

Point-to-point Measurements are pretty straight forward. You pick two points, and the software gives you the results of the distance between those two points. This gives a quick idea of a gap condition, but doesn't cover a large number of other circumstances.

Join DCS Variation Analyst Spencer Strouse and Senior Variation Analyst Gary Bell as they demonstrate how to apply and use a number of different measurement types other than Point-to-Point to help you model faster and get the outputs you need to make decisions.

These Stories on CATIA

No Comments Yet

Let us know what you think