DCS was proud to be a part of SME's new event, and we all hope to continue to support SME in the coming years

The Society of Manufacturing Engineers (SME) is a nonprofit association of professionals, educators, and students committed to promoting and supporting the manufacturing industry. SME helps manufacturers innovate, grow and prosper by promoting manufacturing technology, developing a skilled workforce, and connecting the manufacturing industry. (https://www.sme.org/aboutsme/what-is-sme/)

As a member of SME, DCS provides tools, resources, and lectures to educate the next generation in the tools being used in Industry now and in the future. As part of this outreach, I was able to both sponsor and attend the Symposium this last week on Nov 11th in the school of engineering on the Oakland University campus. (https://oakland.edu/secs/)

At the first SME Ch69 Symposium, SME invited a variety of presenters to showcase new engineering methods being used by manufacturers as well as developments in the school of engineering to better prepare students for the jobs in the market now.

The event began with an opening address from Professor Louay Chamra, Dean of the School of Engineering, welcoming SME, the students, and local professionals. With a focus on the Digital Twin and Quality 4.0, SME is looking to the future of manufacturing and ways to prepare now for what will come tomorrow.

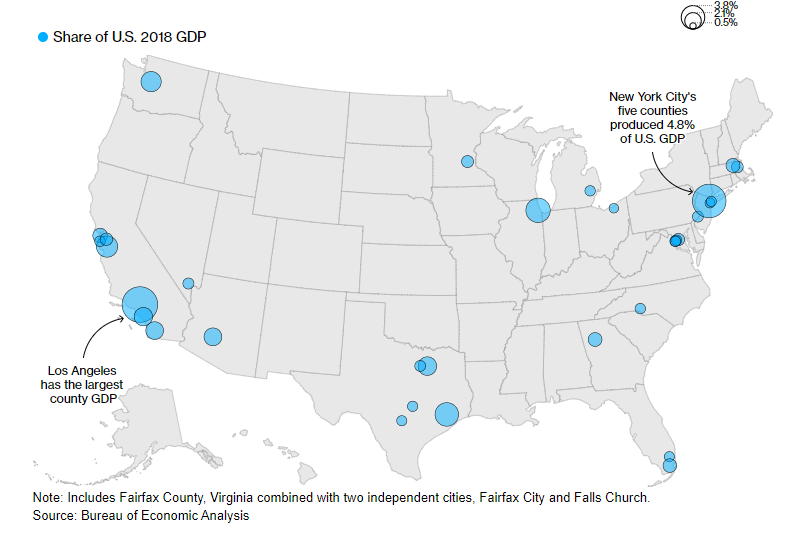

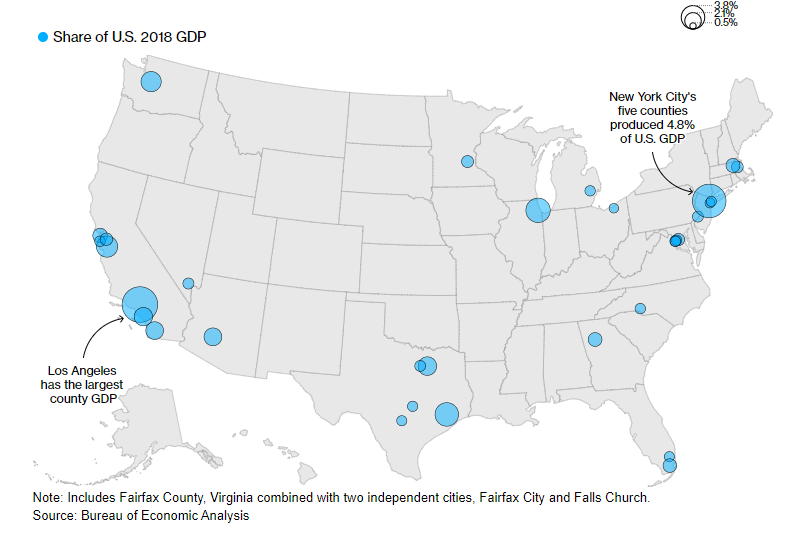

Leading off the evening's talks was Greg Doyle, head of business retention and expansion for Oakland Country who focused on the importance of metro Detroit in the US economy. As one of the centers for industry and innovation, metro Detroit is key to Michigan's future.

The largest 31 counties in the US made up 32% of the US GDP in 2018. -- https://www.bloomberg.com/graphics/2019-us-gdp-concentration-counties/

The largest 31 counties in the US made up 32% of the US GDP in 2018. -- https://www.bloomberg.com/graphics/2019-us-gdp-concentration-counties/

Understanding this, it becomes imperative to train students to develop the skills they need to hit the ground running after graduation, while also incentivizing them to stay in Michigan to further the development of its manufacturing and engineering. Oakland University itself boasts a near 90%+ retention of students who find fulfilling careers in Michigan after graduation.

Migael Suez, PhD, provided a new outlook on traditional assembly. Instead of attaching components to fixtures in order to perform operations, robots can hold parts in order for other robots to perform those same operations on the part.

This does two things: the first, it removes the need for the fixture, and secondly, it allows the robots unparalleled access to the part in order to perform more operations than could be done with the fixture alone.

Fixtures, as a refresher, are assemblies designed to hold parts during the assembly and manufacturing process. They are often one-off or small batch made, custom-designed, and are only usable for a single product and very similar products. This means that not only are fixtures expensive, but they have very short lives before being discarded. The reduction in fixturing is a constant driving force for innovation as a major cost reduction in manufacturing, and this method shows promise as one of the solutions (there won't be a silver bullet, that is a single solution, after all).

You can learn more about Saez's work from his paper on the subject available through ASME at: https://asmedigitalcollection.asme.org/MSEC/proceedings-abstract/MSEC2020/84263/V002T07A012/1095728

Following Migual Saez was DCS' Gary Bell ---

Gary Bell demonstrated how parts in CAD can be upgraded using 3DCS software to include GD&T, Constraints, and Measurements in order to act like real parts. Utilizing Monte Carlo analysis, Bell created hundreds of virtual prototypes that were then analyzed with SPC (Statistical Process Control) in order to find the risk of failure, areas of concern, and any non-conformances that might occur during production.

As a small area of engineering, dimensional engineering has a long shadow. With a shrinking community of experienced professions, there are a lot of openings in dimensional engineering but few people to fill them. As a discipline, GD&T and dimensional engineering are often overlooked in education, and the vision is to add classes specifically for teaching dimensional engineering and its incorporation into CAD to students.

You can learn more about the digital twin in CAD here: https://www.3dcs.com/tolerance-analysis-software-and-spc-systems/3dcs-software

The final presentation from SME was from Professor Robert Van Til, chair of Industrial and Systems Engineering at Oakland University. Professor Van Til demonstrated how, through collaborations with major providers like Siemens, he was able to integrate tools used by major manufacturers into the curriculum and classes at Oakland University.

Visiting other universities, the professor assumed that this was common practice. However, he soon realized that this was a unique collaboration at Oakland University as it unlocked these tools, including Teamcenter as well as advanced simulation tools beyond NX CAD, to the students, undergrad, and grad, as part of their classwork. This was quite different from most universities who treat arrangements with providers as one-off projects to be piloted by grad students and professors only, essentially isolating the tool use and experience to less than a handful of faculty and PhD students, and then immediately losing it after the project ends.

Employers were thrilled to hire new engineers who were already experienced in many of the niche software used in the industry, as well as PLM like Teamcenter. This made their onboarding and training much faster and helped the new engineers get going without feeling lost or behind. It has become such a success that the program is being expanded to include more tools!

Learn more at the Oakland University: https://oakland.edu/careers/systems-engineering-ms/

These Stories on CATIA

No Comments Yet

Let us know what you think