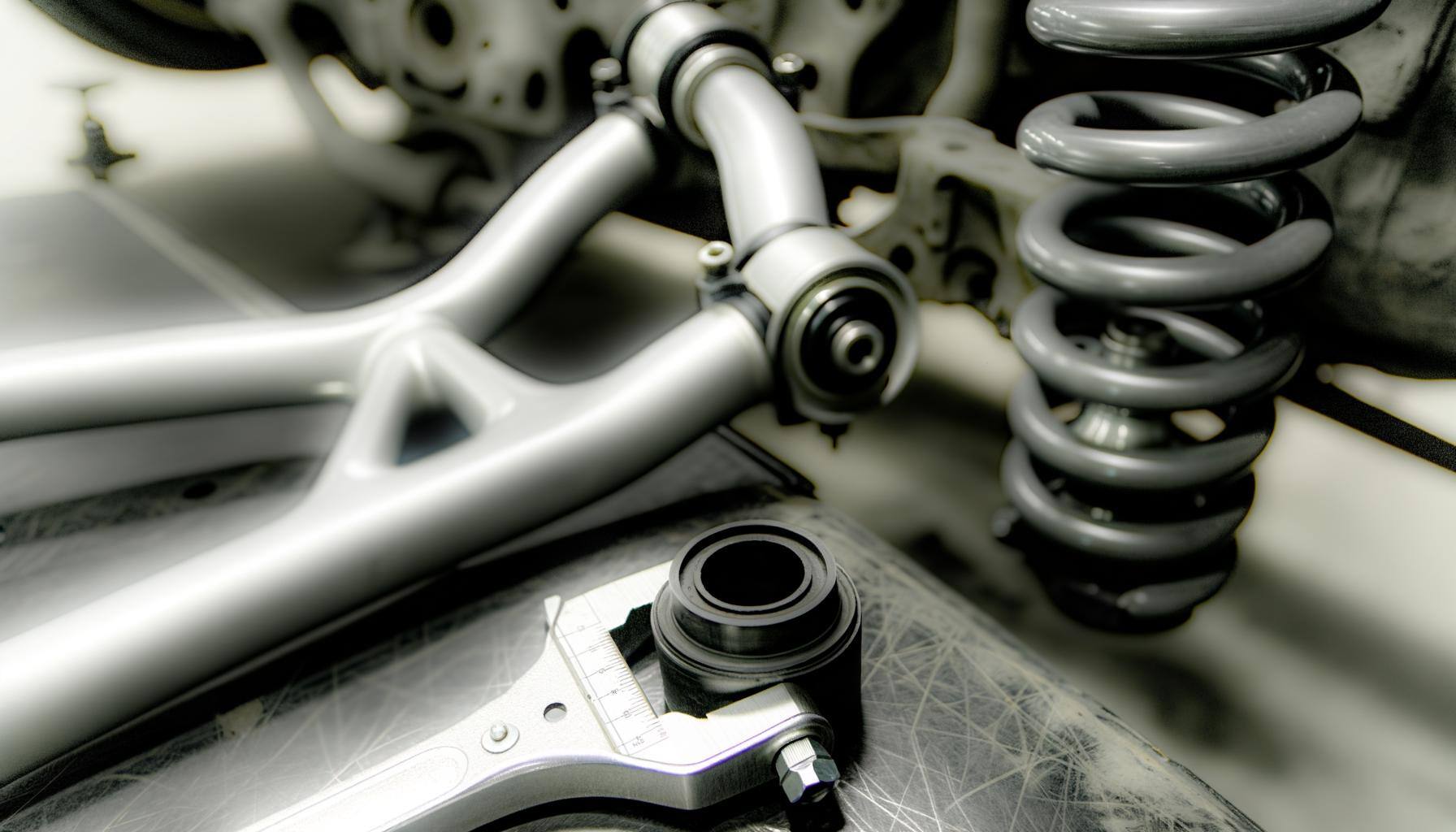

In the world of automotive engineering, suspension systems stand as the unsung heroes that define a vehicle's comfort and handling prowess. These systems serve as the pivotal link between the road and the vehicle's chassis, absorbing shocks and vibrations while maintaining tire contact with the surface. The delicate interplay between springs, dampers, and linkages determines how well a vehicle adapts to various terrains, influencing both ride comfort and overall handling performance.

At the heart of a suspension system's effectiveness lies its ability to manage dynamic forces while ensuring stability and control. The system's components, including control arms, stabilizer bars, and bushings, must work in harmony to achieve this balance. Each element plays a crucial role, from isolating road noise to maintaining optimal wheel alignment. As we delve deeper into the complex mechanics of suspension systems, the importance of precision engineering becomes abundantly clear.

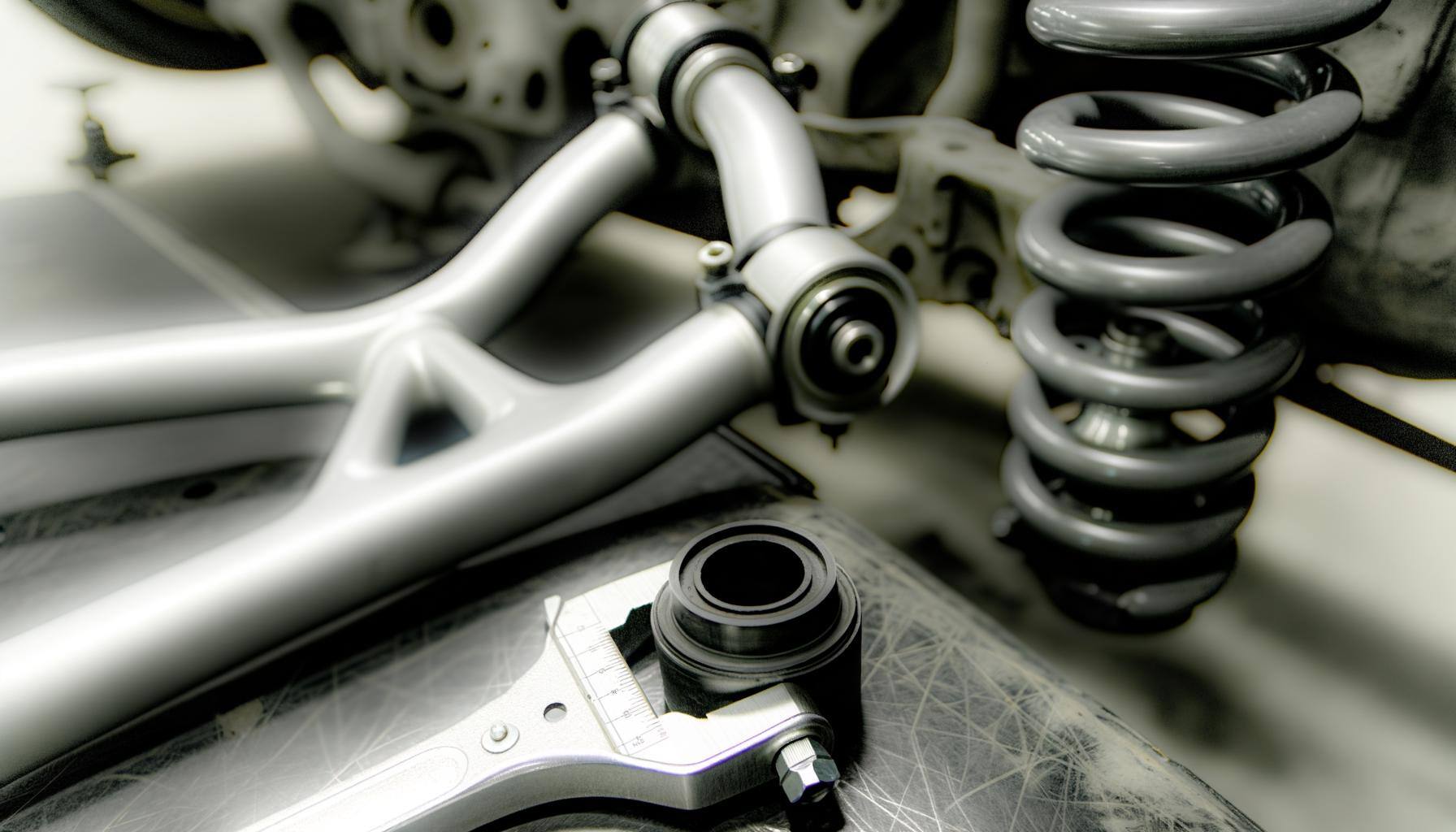

Bushings, made from materials such as rubber or polyurethane, are integral to the functioning of a suspension system. These components act as compliance elements, allowing for controlled deformation under load. The degree of bush compliance can significantly influence ride comfort and vehicle handling, offering an intriguing trade-off between isolation from road irregularities and feedback responsiveness.

High compliance in bushings typically enhances ride comfort by effectively dampening vibrations and absorbing shocks. This results in a smoother driving experience, especially on uneven surfaces. However, excessive compliance might lead to undesirable effects such as increased body roll and a perceived loss of control. On the other hand, low compliance bushings maintain a more rigid setup, offering direct feedback and improved handling precision but potentially transmitting more road noise and vibrations to the cabin.

Achieving the right balance in bush compliance is crucial for optimizing ride quality. Engineers must consider the vehicle's intended use, be it for comfort-oriented daily driving or performance-focused applications, to tailor the suspension setup accordingly.

Kinematic linkages, which include components like control arms, play a critical role in defining the geometry of wheel movement and alignment. These linkages determine key suspension angles such as camber, caster, and toe, all of which influence how a vehicle handles and wears its tires.

Dimensional variations in these linkages can have a profound impact on suspension performance. For instance, a slight change in the length of a control arm can alter wheel travel and affect bump steer characteristics. These changes can lead to uneven tire wear, reduced traction, and compromised handling stability. Therefore, precise dimensional specifications are essential to ensure that the suspension system performs as intended.

Understanding and managing these variations through meticulous engineering can significantly enhance both ride comfort and handling dynamics. Engineers must perform detailed analyses and adjustments to maintain optimal suspension geometry, thereby improving tire contact with the road and ensuring consistent handling performance.

The interaction between bush compliance and kinematic linkage dimensions is a complex yet fascinating aspect of suspension design. These elements do not operate in isolation; instead, they work in tandem to influence the overall dynamics of a vehicle's suspension system.

High compliance bushings can sometimes mask issues arising from dimensional variations in linkages by absorbing some of the resultant forces. Conversely, precise linkage dimensions can mitigate the negative effects of bushing compliance, helping maintain consistent alignment and handling stability. This interplay necessitates a careful balance between the two factors to achieve optimal suspension performance.

For engineers, understanding these interactive effects is crucial for developing a suspension system that offers both comfort and control. This requires a comprehensive approach that considers the combined impact of bush compliance and linkage variations, ensuring that both factors are adequately addressed through precise design and testing.

To fully comprehend the impact of bush compliance and linkage variations, engineers employ advanced testing and simulation techniques. Experimental studies often involve rig testing and on-road evaluations to assess suspension performance under various conditions. These tests provide valuable insights into how different configurations affect ride comfort, handling, and overall vehicle dynamics.

Computational methods, such as finite element analysis and multibody dynamics simulations, complement experimental studies by offering detailed analyses of dimensional changes on suspension behavior. These simulations enable engineers to predict the effects of different bush and linkage setups, allowing for iterative design improvements before physical prototypes are built.

By leveraging these advanced techniques, engineers can optimize suspension systems with a high degree of precision, ensuring that vehicles deliver the desired balance of comfort and handling. This iterative process of testing and refinement is crucial for achieving the perfect suspension setup.

In the quest for superior vehicle dynamics, achieving the perfect balance between ride comfort and handling is paramount. This balance is not a one-size-fits-all solution but rather a tailored approach that considers the specific needs and characteristics of each vehicle. Engineers must weigh the trade-offs between bush compliance and linkage dimensions to deliver a suspension system that meets performance expectations.

Designers must also consider the intended use of the vehicle and the preferences of its target audience. A luxury sedan might prioritize comfort, while a sports car may focus on handling precision. By carefully tuning the suspension system through precise engineering and iterative testing, manufacturers can deliver vehicles that excel in their respective categories.

Continued research and advancements in suspension technology promise to further enhance our understanding of these complex systems. As engineers push the boundaries of what's possible, the future of vehicle suspension looks promising, with ever-improving ride and handling characteristics.

These Stories on CATIA

No Comments Yet

Let us know what you think