Troy, Mich. – Dimensional Control Systems, Inc. (DCS) has joined MSC Software’s Technology Partner Program to focus on improving the workflow between Finite Element Analysis (FEA) and Variation Analysis. As a Software Community Partner of MSC Software, DCS will enhance the connections between the two families of tools to help customers incorporate FEA into their Variation Analysis models.

Traditional tolerance analysis determines the effect of part and assembly deviation from nominal on a product. However, this approach considers all parts as rigid. When these parts are made of flexible materials like sheet metal or plastic, the material reacts to the processes and environments it comes in contact with, causing unexpected build issues.

Traditional tolerance analysis determines the effect of part and assembly deviation from nominal on a product. However, this approach considers all parts as rigid. When these parts are made of flexible materials like sheet metal or plastic, the material reacts to the processes and environments it comes in contact with, causing unexpected build issues.

To combat this unexpected variation, FEA is incorporated into the simulation process. This considers the additional variation caused by clamping, pressing and assembling flexible components, as well as the deformation from thermal effects like welding or material expansion.

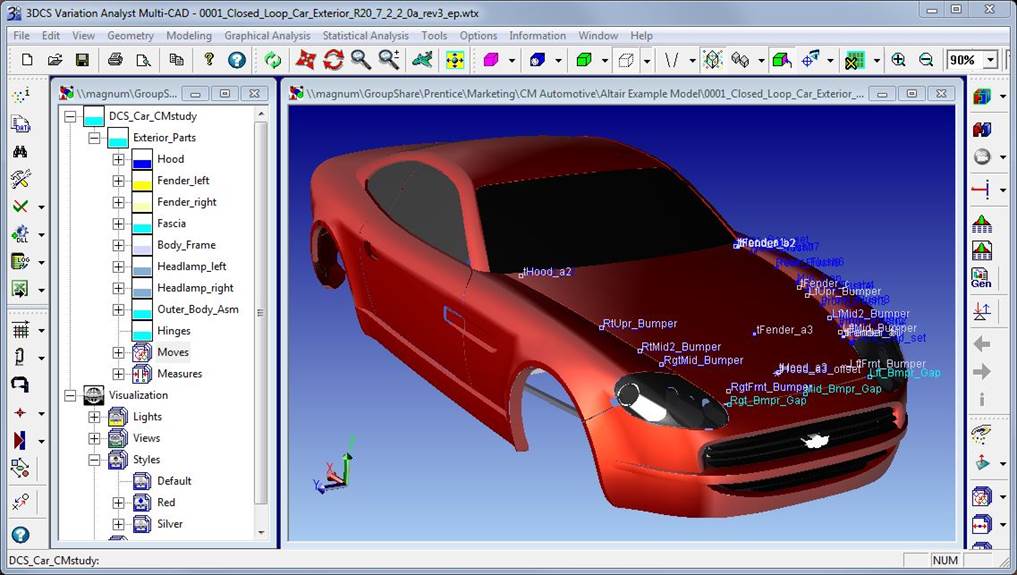

This partnership allows MSC Software’s FEA tools to be combined with DCS variation analysis tools in order to simulate these assembly processes and part deformation to understand and control the overall build variation. The intent is to reduce the cost of quality that stems from variation in the product and results in scrap, rework and warranty claims. These costs often amount to millions of dollars, and by simulating the process before production; many of the contributing issues that create these problems can be identified and solved.

“This partnership allows us to better align our tools to meet the demands of the industry,” said Donald Jasurda, DCS Vice President of Sales. “As 3D simulation continues to advance and take advantage of greater levels of analysis, DCS is working with MSC Software to deliver technology to address the needs of manufacturing companies across all industries.”

The vision for the partnership includes continuing effort to develop streamlined approaches to analysis to give new and experienced users of 3DCS the ability to develop more robust designs. By incorporating connectivity between the two families of products, this partnership promises to deliver greater opportunities to manufacturers to reduce their cost of quality.

The vision for the partnership includes continuing effort to develop streamlined approaches to analysis to give new and experienced users of 3DCS the ability to develop more robust designs. By incorporating connectivity between the two families of products, this partnership promises to deliver greater opportunities to manufacturers to reduce their cost of quality.

For more information contact DCS by clicking here

DCS has been supporting quality management in industries including automotive, aerospace, medical device, electronics and industrial machinery for over 20 years. DCS solutions are used daily by companies like Airbus, BMW, GM, LG, Nissan, Phillips, Sony, Textron Aviation and VW. By applying DCS's 3D Model Based environment for Predictive Variation Analysis and Responsive SPC, manufacturers have reduced quality management costs related to yield, scrap, rework and warranty issues. Read more at www.3dcs.com.

MSC Software is one of the ten original software companies and a global leader in helping product manufacturers to advance their engineering methods with simulation software and services. As a trusted partner, MSC Software helps companies improve quality, save time, and reduce costs associated with design and test of manufactured products. Academic institutions, researchers, and students employ MSC's technology to expand individual knowledge as well as expand the horizon of simulation. MSC Software employs 1,100 professionals in 20 countries. For additional information about MSC Software's products and services, please visit: www.mscsoftware.com.

These Stories on 3DCS

No Comments Yet

Let us know what you think