Metrologic and DCS Proudly Exhibit End-to-End Solution at CMSC

The Coordinate Metrology Society

The Coordinate Metrology Society is comprised of users of 3D portable and stationary measurement technologies, service providers, and OEM manufacturers of close-tolerance industrial coordinate measurement systems, software, and peripherals.

The membership gathers each year at their annual Coordinate Metrology Society Conference (CMSC) to gain knowledge of advancements and applications of any measurement system or software solution that produces and uses 3D coordinate data. The portable metrology systems represented at CMSC include articulating arms, CMMs, laser trackers, laser radar, photogrammetry /videogrammetry systems, scanners, indoor GPS, and laser projection systems.

--- World’s leading professionals in a wide variety of industries looking for the latest in technology solutions

--- Technical presentations industry-wide and from across the country draw large attendance from the core of the industry

--- Hands-on workshops & breakout sessions allow attendees to interact with exhibitors in ways traditional tradeshows don’t

--- Exhibitors are welcome to host user group meetings for key clientele on-site during the conference

--- Our Measurement/Education Zone offers hands-on opportunities with the exhibitors and keeps the educational aspect of our conference an easy sell for prospective conference attendees

--- Exhibitors can pre-register for the Level One and Level Two Certification Program

--- Networking: Share discoveries and advancements, best practices, success stories, and solutions with conference attendees

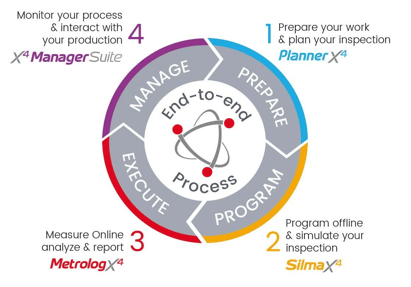

DCS and Metrologic, both SANDVIK companies, have come together to offer the only true End-to-End Solution for manufacturers.

See part of the end-to-end solution on-demand

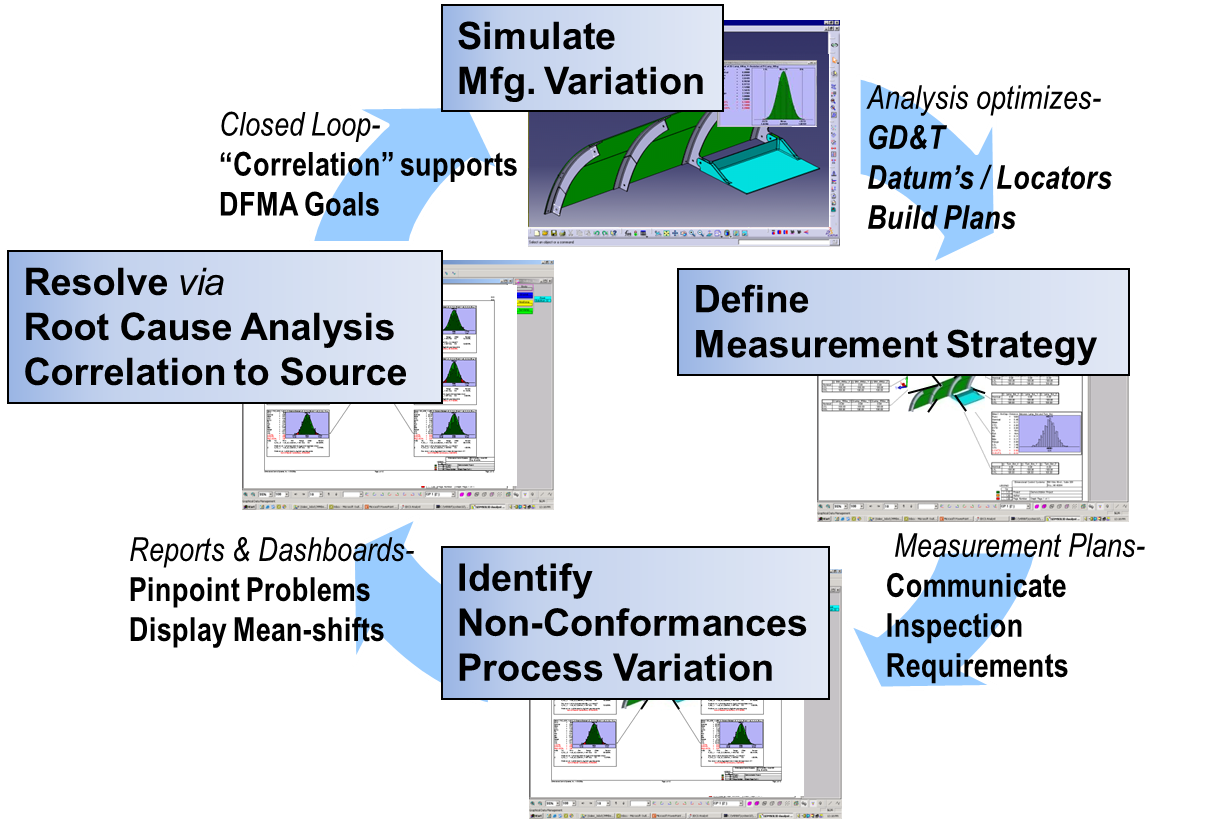

Combining simulation, design, measurement planning, inspection, and quality monitoring and management, the End-to-End Solution ensures high quality and reduced defects across the entire Product Life Cycle.

On display at the conference, attendees will be able to walk the entire End-to-End Solution, from 3DCS simulation studies, Silma planning, CNC manufacture, robotic inspection, inline inspection (DWFritz ZERO Touch), measurement, analysis, SPC, and real-time monitoring. Powered by the Digital Twin, and carried through the process with QIF, the End-to-End Solution offers a complete hardware agnostic solution to solve manufacturing quality and improve supplier quality.

Keep an Eye on CMSC with Linkedin by using the hashtag #CMSC2022

These Stories on CATIA

No Comments Yet

Let us know what you think