Thursday 23rd - Integration of Physical Test with Analysis & Simulation Track

DCS expert Tom Oetjens, Senior Dimensional Analyst and Gear Specialist, discusses analysis for gear assemblies for electric vehicle motors to optimize for performance and assembly.

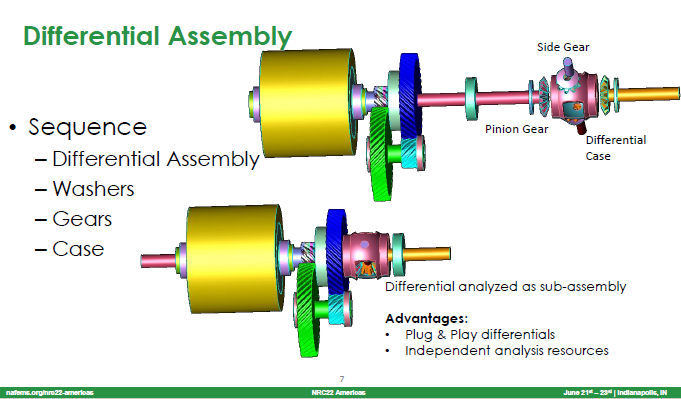

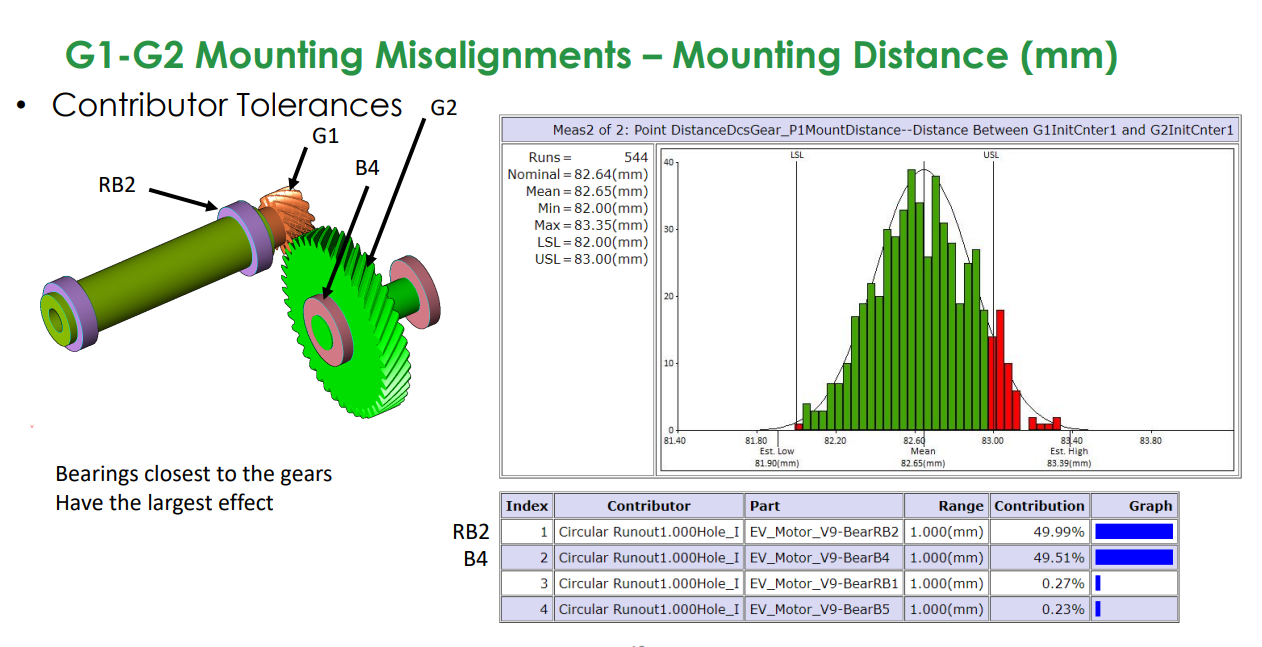

The performance of an Electric Vehicle Power Unit is directly connected with critical tolerances. Tolerances drive opportunities for performance enhancement with cost reduction. The upfront method illustrated uses digital technology to create a parametric family of designs with statistical tolerances as the parameter. Once an adjustable statistical tolerance has been established, the tolerances can be split into the individual components.

For the example design, the bearing represents the combination of the gear grade, bearing specifications, and the housing specifications. Dividing the tolerance up using statistical cost analysis can balance the design tolerances at the lowest cost. Gear micro geometry in the form of gear crowning, and gear backlash or tooth clearance is another example of the method. By adjusting the tolerance as a parameter provides the geometric information to ensure the gear system backlash and flank patterns meet the requirements specifications.

Using this form of statistical morphing, this digital model can simulate the measurements of the final manufactured drive system as well as each component for an excellent concept design or physical “mule” drivable concept vehicle.

No Comments Yet

Let us know what you think