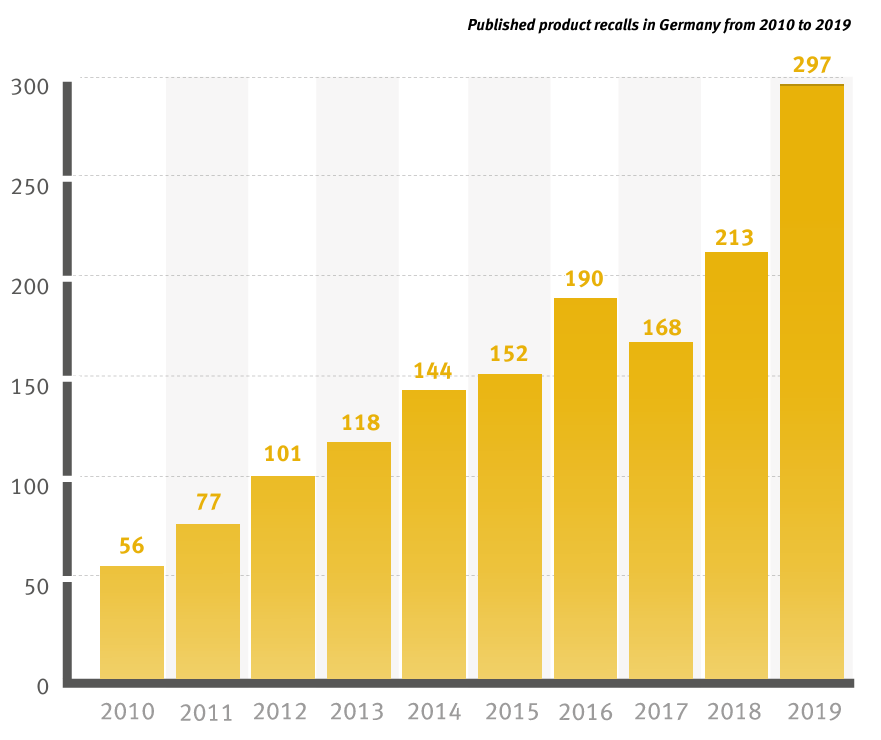

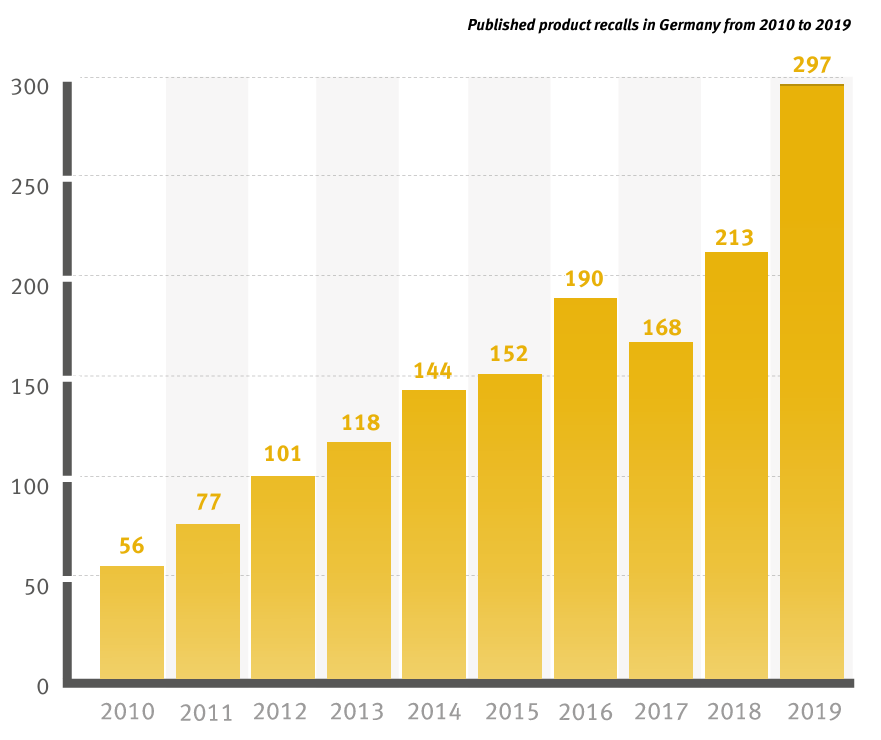

Businesses started relying on quality as an image factor long before marketing even became a business function. Nowadays, however, reports of a broken quality promise can spread through social media in seconds – and cause a loss of reputation just as quickly Product recalls often attract the greatest attention. Be it faulty brakes or metal in our milkshakes – the number of recalls is on the rise.

For the businesses involved, the loss of image quickly leads to a loss of income. This stems from a combination of costs from the recall, compensation payments, reduced sales revenue, etc.

Picking up an engineering handbook won’t help you find the “right” values for quality. Businesses certainly rely on numbers and figures to plan, measure, and assess quality, but these must always be calculated within context of the individual business.

For us as humans, our understanding of quality is affected by cultural aspects, social background, and our worldview. Businesses, on the other hand, primarily derive their approach to quality from their respective business model. This freedom in defining one’s own approach to quality means that company management has a constant duty to communicate that definition. It must ensure that all employees are aware of the company’s quality concept and act in accordance with it.

In our consulting on quality problems, we encounter a recurring phenomenon: in the end, problems come down to a lack of shared understanding. A business may have well-documented operating procedures, but that doesn’t mean that everyone has internalized them, and unwritten but ingrained patterns may exert a contrary influence.

Most companies focus on the technical, but tolerances and machine settings alone won’t give you a secure quality basis – your optimization task must take additional variables into account. As an example of this in action, an anecdote from my employment with a Tier 1 auto supplier.

We were having trouble with the assembly of a new car component and our workers kept complaining that the parts didn’t fit right. We were at a loss because we had toleranced, simulated, and calculated all the components, and all our measurements were giving us the right values.

So what was causing our assembly problems?

After painstaking research, we discovered that one of the components was being delivered from a plant unit some distance away – via a cobblestone road, and the cargo wasn’t packaged to account for that. Transport paths, weather influences, team composition during a shift or performance deviations in a new facility – it’s important that you develop an awareness of the multitude of factors that may influence quality.

Of course, it isn’t economically feasible to research, let alone digitalize, every last detail. But you will achieve better results if you keep your ear to the ground and try to do more than just satisfy what is currently the accepted standard.

These Stories on 3DCS

No Comments Yet

Let us know what you think