Learn how DCS and CENIT showcase cutting-edge variation analysis tools at the Mikrocentrum event in the Netherlands.

The Mikrocentrum Technology Conference in the Netherlands is a gathering of key manufacturers who are interested in improving their product quality while effectively managing the risks associated with non-conformance in production.

Hosted by Mikrocentrum, this conference provides a platform for manufacturers to explore innovative solutions and strategies for raising their quality standards.

The conference aims to bring together industry leaders and experts to discuss the latest advancements in technology and share insights on best practices for quality control in manufacturing.

Attendees will have the opportunity to learn from industry experts, participate in interactive sessions, and network with like-minded professionals who share a common goal of achieving excellence in manufacturing.

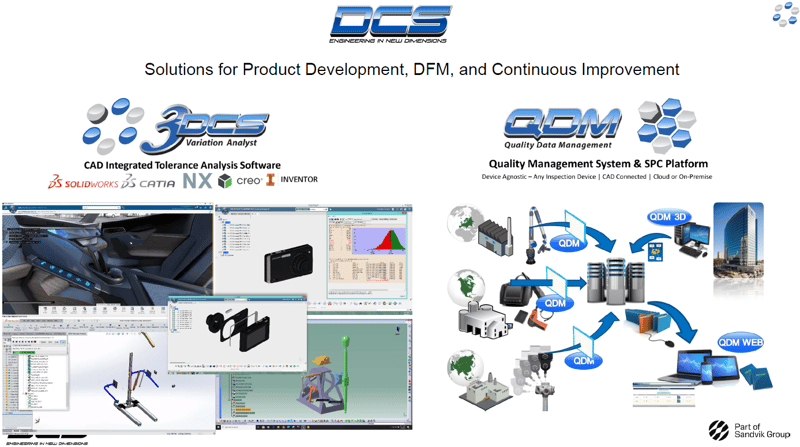

DCS has partnered with CENIT to showcase cutting-edge tolerance analysis software at the Mikrocentrum event.

This collaboration brings together the expertise and resources of both companies to provide manufacturers with advanced tools for analyzing and controlling variations in their production processes.

The tolerance analysis software developed by DCS and CENIT enables manufacturers to accurately assess the impact of variations on product quality and make informed decisions to minimize non-conformance.

By leveraging this software, manufacturers can optimize their production models and improve overall quality while reducing the risks associated with non-conformance.

During the Mikrocentrum event, the DCS and CENIT team will demonstrate the capabilities of their 3DCS software for model optimization.

Using Product Manufacturing Information (PMI), the team will showcase how the 3DCS software can optimize models for downstream use, ensuring accuracy and efficiency in the manufacturing process.

The software enables manufacturers to prepare precise measurement points and determine critical characteristics, allowing them to focus on high-risk features and improve overall product quality.

By incorporating the 3DCS software into their workflow, manufacturers can streamline their design and simulation processes, leading to better measurement and manufacturing quality control.

One of the key advantages of the 3DCS software is its seamless integration with quality management processes.

The software provides a comprehensive solution that connects with existing quality management systems, allowing manufacturers to effectively manage and control their production processes.

By leveraging the capabilities of the 3DCS software, manufacturers can identify and address quality issues at an early stage, minimizing the risks of non-conformance and ensuring that products meet the required quality standards.

The software empowers manufacturers to make data-driven decisions, optimize their manufacturing processes, and continuously improve product quality.

As part of the Sandvik Group, the 3DCS software offers a complete manufacturing solution for quality control.

From early design and simulation to measurement and manufacturing quality control, the metrology solution provides a seamless workflow that enables manufacturers to achieve excellence in every stage of the production process.

By leveraging the capabilities of 3DCS software, manufacturers can ensure that their products meet the highest quality standards and deliver superior performance to their customers.

The software empowers manufacturers to optimize their manufacturing processes, reduce costs, and enhance overall product quality, ultimately leading to increased customer satisfaction and business success.

These Stories on 3DCS

No Comments Yet

Let us know what you think