Unlock the future of manufacturing accuracy and productivity with blue laser scanning technology, where unmatched precision meets rapid data capture. Discover how the Metrologic Suite processes scanned data and point clouds quickly and efficiently.

Join the Webinar to See It Yourself:

When: Thursday, Sept 25th, 11 am EST

Where: Gotowebinar

Register FREE: Click Here to Register

Blue laser scanning technology leverages the shorter wavelength of blue light to achieve higher precision and finer detail capture compared to traditional red lasers. This is particularly advantageous in measuring shiny or reflective surfaces, where blue lasers minimize noise and enhance accuracy. The Kreon Zephyr III 3D scanner utilizes this principle to deliver exceptional measurement accuracy and detail resolution, even on challenging surfaces.

Moreover, the Zephyr III's blue laser line width of up to 300 mm allows for faster data acquisition by reducing the number of passes required to scan an object. This efficiency boost is crucial for high-volume production environments where time is of the essence.

The integration of blue laser scanning technology into quality control processes represents a significant leap forward for manufacturing industries. The Kreon Zephyr III scanner's ability to deliver high-resolution data, with a resolution up to 15 µm between points, ensures that even the smallest details such as engravings, holes, and part edges are accurately captured.

By enabling comprehensive and precise inspections, manufacturers can identify and rectify defects early in the production process, thereby reducing rework and scrap rates. This not only enhances product quality but also improves overall manufacturing efficiency and cost-effectiveness.

Efficiency on the production line is paramount, and the Kreon Zephyr III 3D scanner excels in this regard. Its compatibility with the PH10 motorized head allows for multiple orientations during scanning, facilitating a fully automated inspection process without compromising accuracy.

Additionally, the scanner's design allows for seamless transitions between scanning and probing operations within the same measurement range. This integration eliminates the need to remove the scanner for probing, thereby streamlining workflows and enhancing productivity.

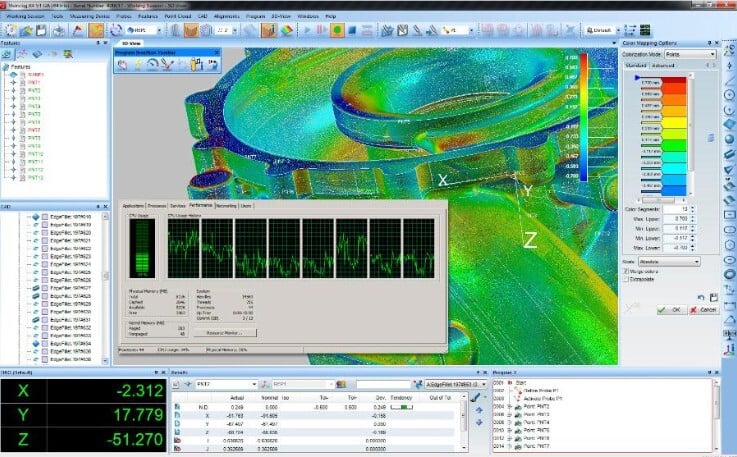

The Metrologic Suite is robust software designed to power your blue light scanner and CMM, enabling rapid analysis of data clouds for precise dimensional inspection.

SilmaX4 lets you simulate scanning paths and create measurement programs offline, so you can validate and fine-tune routines before deploying them—ensuring optimal efficiency and clearance.

MetrologX4 connects directly to your hardware, processes measurement data at high speed, and streamlines critical tasks like tolerance evaluation, reporting, and process control.

Join DCS and Metrologic Group, with guest Burton Precision, for a webinar featuring the new Zephyr III scanner and Metrologic Suite. Discover how these advances can elevate your quality program.

These Stories on 3DCS

No Comments Yet

Let us know what you think