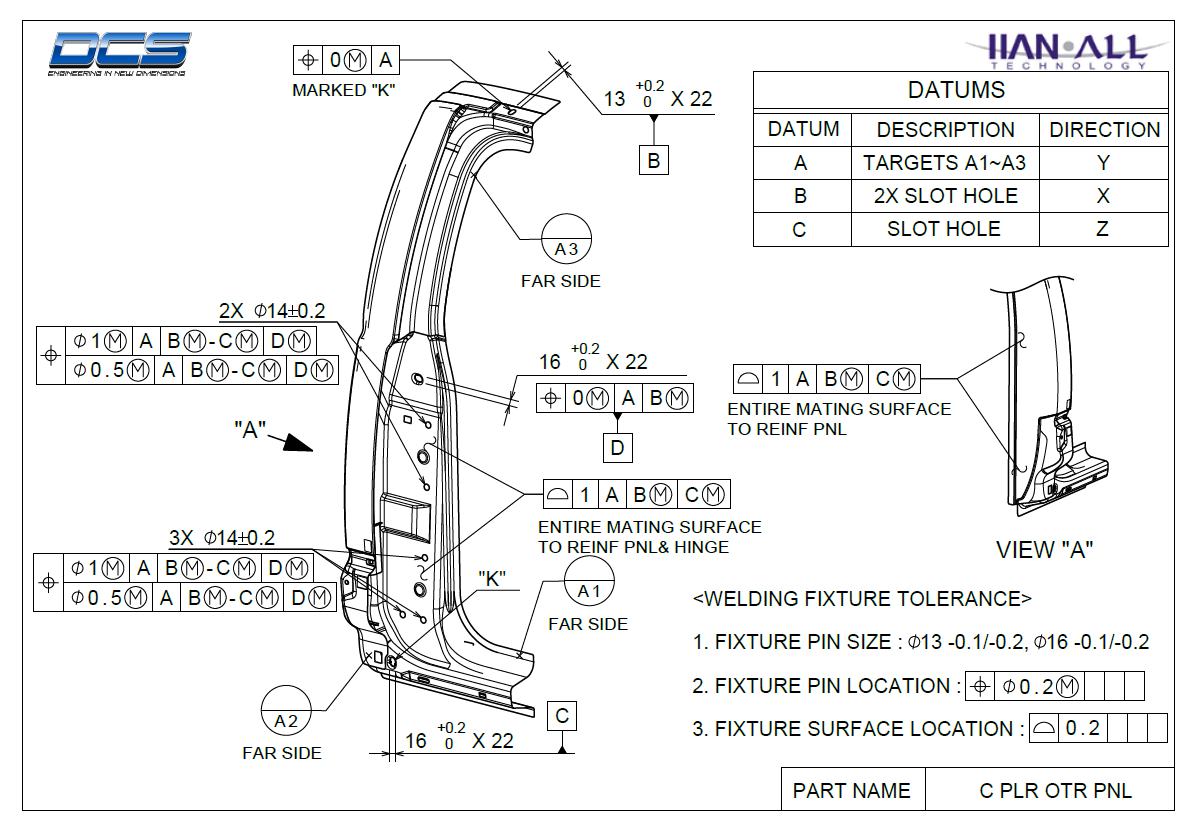

Many businesses are still clinging to 2D drawings or a combination of 2D and 3D CAD renderings. Although 2D drawings may feel comfortable to use, they can actually cause problems throughout the design and manufacturing process. For example, any change made to a 2D drawing has to be manually applied. Unfortunately, drawings can be modified at any point along the workflow, leading to problems with the resulting manufactured part (and eventually, the entire system).

2D Drawings are very useful tools, but hard to keep properly updated and communicate downstream

2D Drawings are very useful tools, but hard to keep properly updated and communicate downstream

The hybrid approach is ineffective as well, as designers can make errors while manually entering 2D data into the 3D model. Additionally, any company that is still relying on 2D drawings will find that it is going the way of the dinosaurs. The hyperfast evolution of industrial technologies, such as the industrial "internet of things" and edge computing, are quickly altering workflows and data usage in manufacturing. Companies that capitalize on these disruptive technologies are migrating to entirely software-based designs because they increase competitiveness (e.g., faster time to market) and improve access to clients and suppliers.

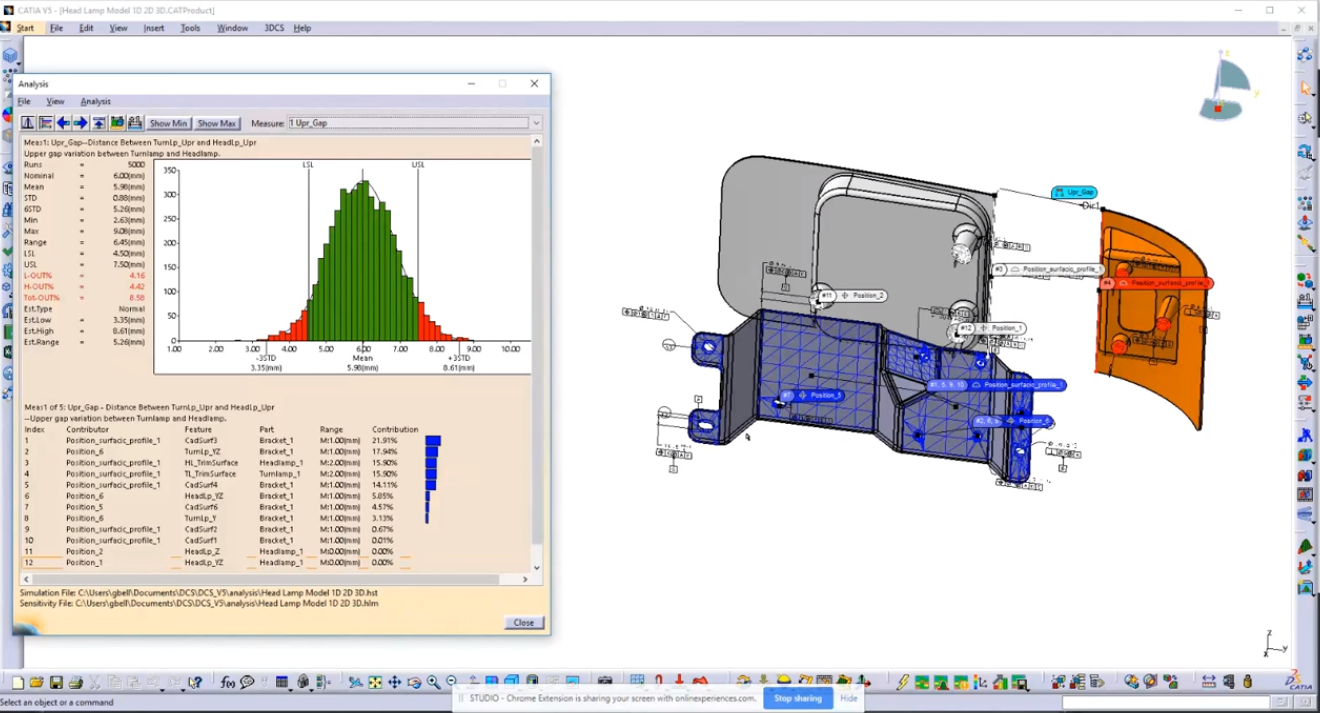

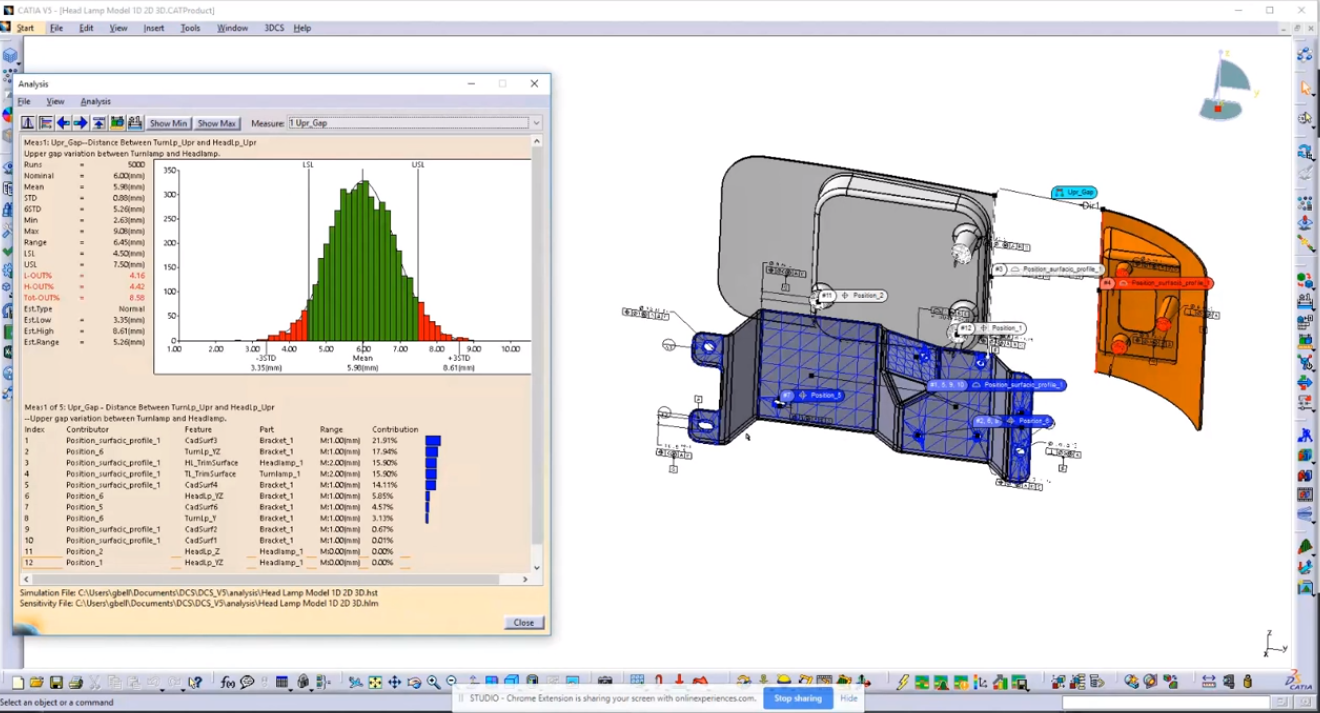

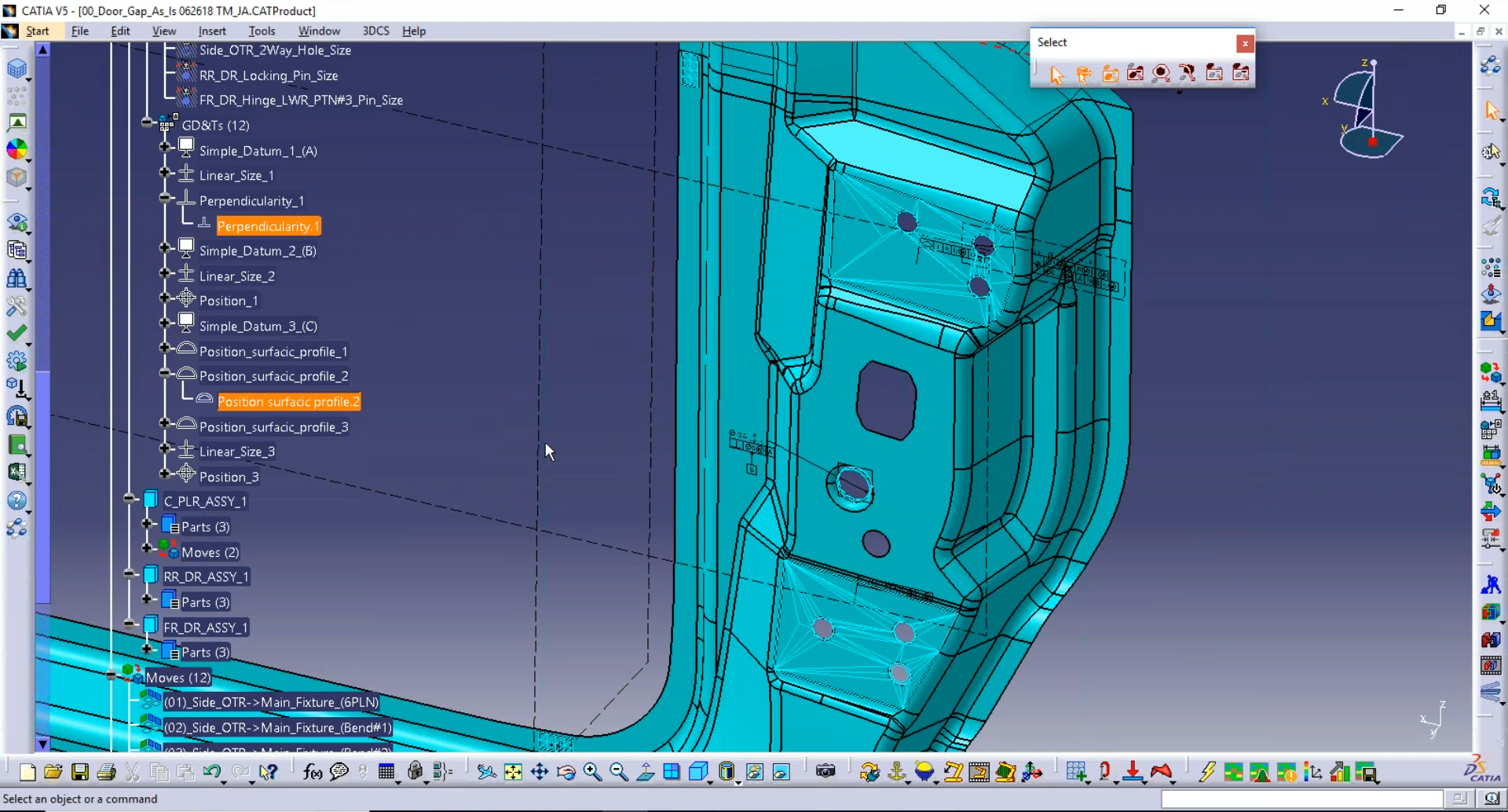

By saying goodbye to 2D drawings, businesses are welcoming automated solutions that can bolster the design and creation process. The implementation of MBD with digital GD&T naturally leads to the utilization of a key cost-saving resource: the digital twin. This is a virtual 3D rendering of a real-life product or system that offers significant benefits. It allows for the assessment of a system's capabilities throughout its life cycle and highlights potential performance issues before processes are implemented or products are manufactured. The digital twin also optimizes a range of models and simulations associated with the life cycle of a product and allows for the improvement of designs with new data. By using MBD with GD&T, the digital twin will include all of the data necessary for users to be able to understand and utilize the design in one compact, easy-to-access and consistent artifact.

By saying goodbye to 2D drawings, businesses are welcoming automated solutions that can bolster the design and creation process. The implementation of MBD with digital GD&T naturally leads to the utilization of a key cost-saving resource: the digital twin. This is a virtual 3D rendering of a real-life product or system that offers significant benefits. It allows for the assessment of a system's capabilities throughout its life cycle and highlights potential performance issues before processes are implemented or products are manufactured. The digital twin also optimizes a range of models and simulations associated with the life cycle of a product and allows for the improvement of designs with new data. By using MBD with GD&T, the digital twin will include all of the data necessary for users to be able to understand and utilize the design in one compact, easy-to-access and consistent artifact.

Including GD&T into your Model Based Definition - MBD - Model creates a single source for manufacturing information

The digital twin is a virtual copy of a real-life system or part, and it requires the data nourishment provided by a digital thread. This is a communication framework that connects the disparate data sources in the manufacturing process and allows for a holistic view of a part throughout its life cycle. By combining these solutions, businesses can create a living, complete 3D artifact that can be utilized in multiple places at different times. The digital twin is a large driver of promoting quality improvements.

Your Digital Twin becomes a digital prototype of your product

The utilization of digital twins and digital threads is long overdue. In an article in Industry Week, Conrad Leiva, vice president of product strategy and alliances of iBASEt, noted that many companies utilize a throw-it-over-the-fence approach to managing the handover of a design. For example, the designer develops the initial 3D model and then hands it over to the next department involved in the process, which is Manufacturing Engineering. After this department has finished creating 2D drawings from the 3D model (wasting time and resources in the process), it then tosses it to Quality. The process continues throughout the workflow, with each department working on the design without input from the other departments. Each department involved in the workflow then silos its own data, which can result in design errors, misunderstandings and clarification delays.

This process clearly has difficulties, not only in the reduction in communication about the design but also in the wasted resources as departments wrangle with issues that could simply be resolved if one model was shared and accessible to all.

Leiva points out that the utilization of the digital twin and digital thread make the entire life cycle more effective and efficient through the improved use of data and communication (for example, the designers work with manufacturing engineers to create the original 3D model and develop the images for the process directions). The digital twin allows for the better movement of resources: Instead of bringing an expert on-site, the expert can examine the digital twin on their own remote computer. Multiple stakeholders can view the same digital twin and work from the same design. When changes are made, the entire collective of stakeholders immediately obtains an updated copy of the artifact, reducing confusion and human-created errors.

In Testing the Digital Thread in Support of Model-Based Manufacturing and Inspection, Hedberg and his colleagues noted that the digital thread allows for real-time design and analysis, automated artifact development and improved collaboration. (There are, incidentally, some problems with its implementation, but some of these are related to the way companies are approaching the technology rather than issues with the technology itself.) However, even with the challenges presented, MBD designs utilizing the digital thread have superior outcomes compared with paper-based creations.

GD&T within the MBD framework promotes the usage of the digital thread because it includes the complex language of tolerancing inside the model, eliminating the need to add it in manually and increasing the ability of all stakeholders to fully comprehend and make use of the design. Digital GD&T drives the process by becoming the single source of information for the model. This not only streamlines the entire process and increases collaboration, but it also ensures that the created parts will be better integrated into their target systems.

Including the GD&T in the MBD Framework drives the process by becoming the single source, improving communication and collaboration

Digital GD&T improves the functions of integrated tools. Since the computer-based model includes all the needed data for development, it no longer relies on multiple human inputs, which naturally increase error. The models can therefore be created directly by manufacturers or even via laser printer, since the 3D design is the only artifact in the process.

Digital GD&T helps to drive the adoption of MBD. Its abilities to streamline the design and development process due to its comprehensive data set, reduce the need for human-inputted data and promote more collaboration through a single artifact all support reduced time to market, better designs, increased comprehension and superior collaboration. Digital twins and the reliance on digital threads enhance product and workflow development through their utilization of real-time data and ability to capture a part or process well enough to modify or improve it before problems arise.

Perhaps the most important aspects of incorporating GD&T via MBD are the efficiencies and cost savings produced. Businesses that fully embrace these data-driven technologies provide a boost for themselves in the marketplace by creating better products and designs while saving money and reducing scrap. Businesses still relying on 2D drawings will soon find that the designs on them are not worth the paper that they are printed on.

These Stories on CATIA

No Comments Yet

Let us know what you think