Explore how real-time monitoring transforms metrology, enhancing accuracy and efficiency in industrial applications.

Real-time monitoring in metrology involves the continuous observation and measurement of manufacturing processes as they occur. This enables immediate detection and correction of any deviations or errors, ensuring that the manufacturing process remains within specified tolerances. By providing instant feedback, real-time monitoring helps in maintaining high standards of precision and accuracy in measurements.

In metrology, precision is paramount, and real-time monitoring provides the necessary data to uphold these standards. This involves using advanced sensors and measurement tools that feed data directly into monitoring systems, allowing for immediate analysis and action. As a result, manufacturers can ensure that their processes are consistently producing parts that meet exact specifications.

Real-time data is a game-changer for boosting both precision and efficiency in metrology. By continuously collecting and analyzing data, manufacturers can identify and address variations in the production process quickly, reducing the likelihood of producing defective parts. This not only improves the overall quality of the products but also enhances the efficiency of the manufacturing process.

Moreover, real-time data allows for the optimization of manufacturing workflows. By having access to up-to-the-minute information, companies can make informed decisions about equipment maintenance, process adjustments, and resource allocation. This leads to reduced downtime, lower operational costs, and an overall increase in production efficiency.

One of the most significant impacts of real-time monitoring on quality control is the ability to look for trends before bad parts are made. By analyzing real-time data, manufacturers can spot anomalies and trends that may indicate potential issues, allowing them to take corrective action before defective products are produced.

Taking action before having to stop the line is another critical benefit. Real-time monitoring enables manufacturers to make adjustments on the fly, reducing the need for costly and time-consuming production halts. This ensures a smoother production process and minimizes disruptions.

Faster root-cause analysis is another advantage. With real-time data, identifying the source of a problem becomes much quicker and more straightforward. This allows for swift resolution of issues, ensuring that production can continue with minimal interruption and maintaining high-quality standards.

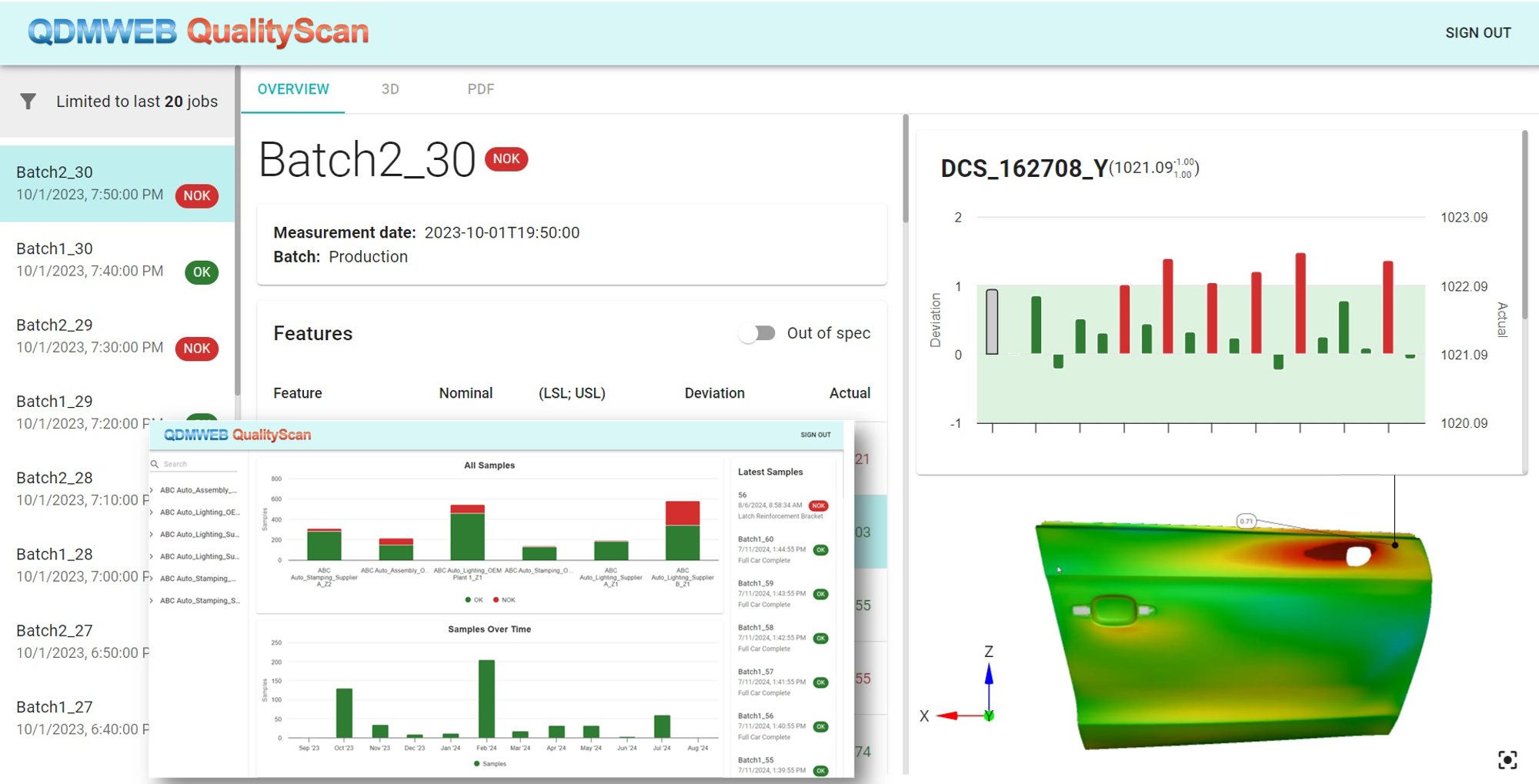

Technological advancements are at the heart of real-time monitoring capabilities in metrology. Solutions like QDMWEB QI deliver real-time visibility across an organization, providing comprehensive insights into manufacturing processes. These technologies integrate various data sources, offering a unified view that enhances decision-making and operational efficiency.

QDMWEB QI, for instance, enables organizations to monitor their processes in real-time, ensuring that any deviations are promptly addressed. By leveraging these advanced tools, manufacturers can maintain stringent quality standards, improve productivity, and reduce costs. The continuous evolution of these technologies promises even greater precision and efficiency in the future, driving the industry forward.

Ready to See It in Action?

Join DCS, Metrologic, and ZeroTouch at IMTS next week to see how Real-Time Monitoring can impact your quality metrics -->

These Stories on CATIA

No Comments Yet

Let us know what you think