The Process Capability Database is a database of tolerances and processes that can be incorporated into your model.

What this means is that you can create tolerances from the database, linking those tolerances to a spreadsheet. This spreadsheet has some suggested tolerances, but is essentially user defined. Every company has different processes and different suppliers that can hold to different tolerances. This makes a generic, catch all database nearly impossible.

However, if you don't have access to company known tolerances, you can use general tolerances based on standards, like ISO standards, or based on historic data and previous models.

By connecting your tolerance to the database, you can then modify the database to instantly modify all connected tolerances. This gives you access to a global key to all tolerances across your entire model.

To quickly change tolerances across your model, you can use Excel Export/Import.

There are two methods that can be used, based on your licensing:

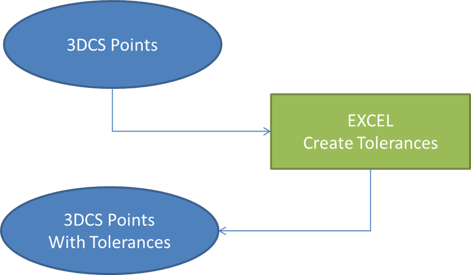

1. If you have EXCEL CREATE ADD-ON Modules, you can create points or select points on your model, and use Excel Export to export a spreadsheet of those points. From here, your can add tolerances to your points, use EXCEL CREATE to load the spreadsheet back into 3DCS, and update all of your points with Tolerances. [Requires 3DCS Add-on]

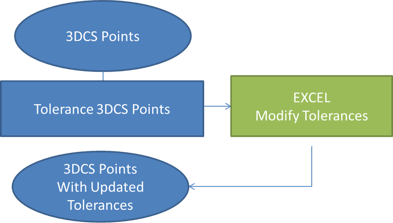

2. Method two is for those without Excel Create. Without Excel Create Licensing, you can only modify existing features, you cannot create new ones. Therefore, you create tolerances on your parts, and can then export an Excel Spreadsheet of those Tolerances to quickly update them. [Included in base 3DCS]

Using spreadsheets does have some drawbacks. For one, it takes all of your points out of context. When tolerancing with a spreadsheet, you have only your point name to go by, and all of the model context is removed. In addition, you are modifying outside of a part tree, so it can difficult to see the relationship of the point. Lastly, it can be more difficult to check your work. When working in the software, you can use other tools and analysis to check your design and make iterative changes instead of global changes.

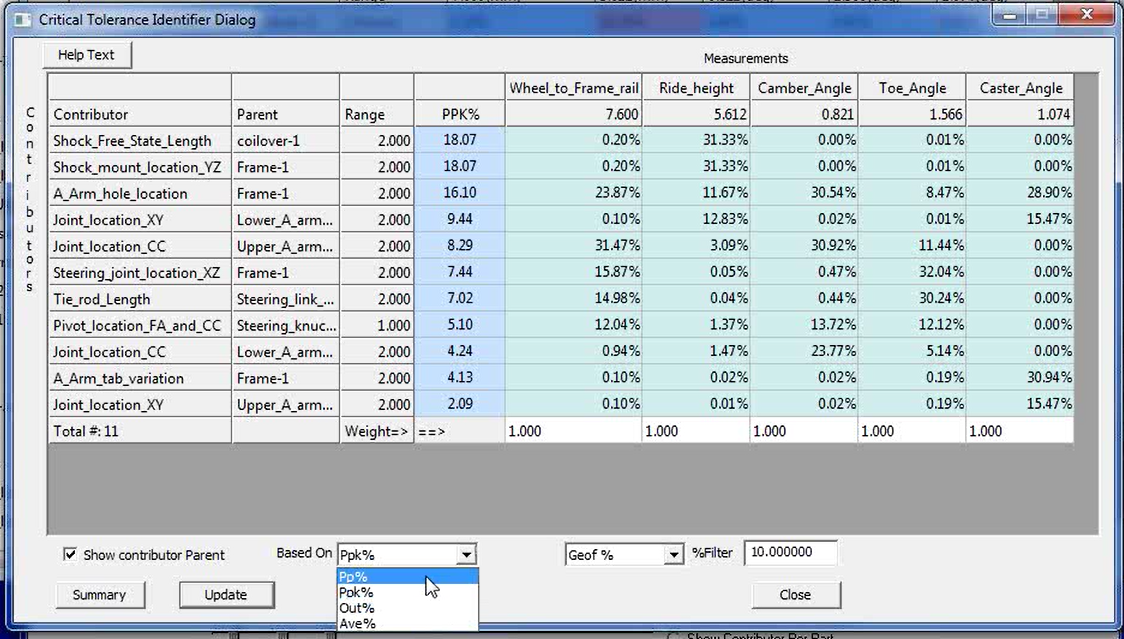

AAO has 4 tools to help you work with your models in new ways. For large models, the most valuable is the Advanced Analyzer Matrix. This produces a matrix of all tolerances or contributors across the model in a single window. From here, you can color code the features based on specific criteria and change any of the inputs to see how it affects the overall product. Better yet, none of the changes are pushed to your model until you select Update Model. [Requires Add-on Module]

This lets you see all of your products features in a single window, change them, and see how those changes affect your product, then revert back without actually changing your model. You can test ideas, make quick alterations to see if they affect your model, conduct instant What If studies.

This global view of your model increases modeling efficiency and reduces the time it takes to modify, analyze and optimize large models in 3DCS.

These Stories on 3DCS

No Comments Yet

Let us know what you think