Discover how automation is revolutionizing the manufacturing industry and what you can do to stay ahead.

Discover how automation is revolutionizing the manufacturing industry and what you can do to stay ahead.

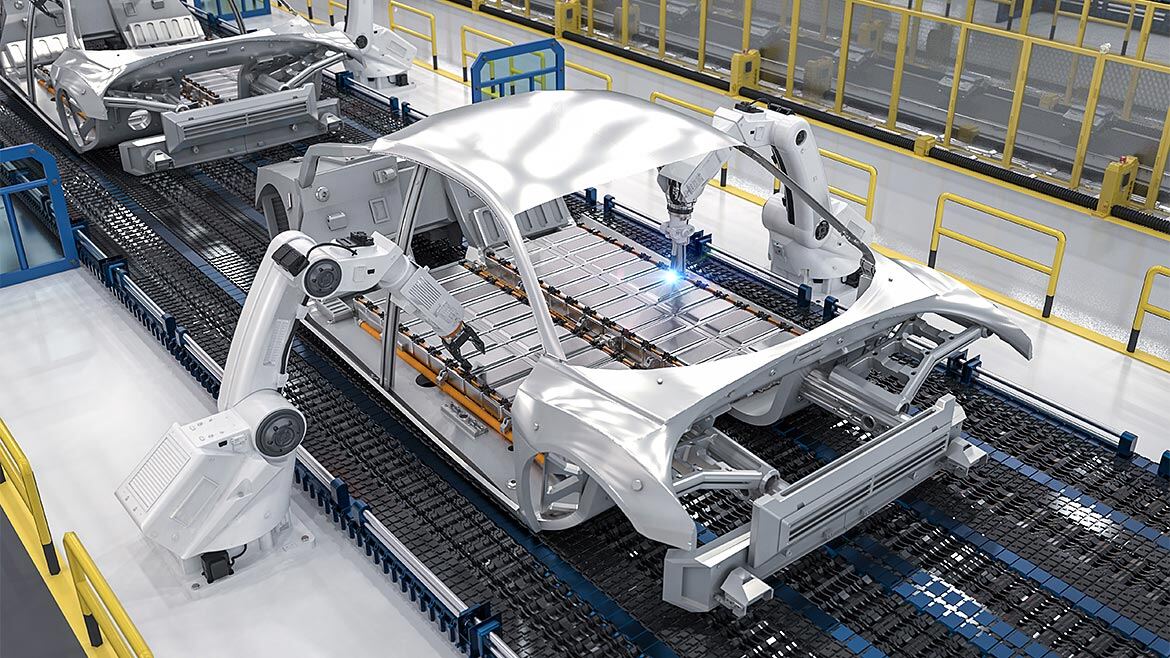

Automation in manufacturing has come a long way, evolving from simple mechanization to sophisticated, self-operating systems. The journey began with basic manual operations, gradually integrating more advanced machinery and technology, leading to today's 'lights-out' production facilities where human intervention is minimal.

This evolution is driven by the industry's constant pursuit of efficiency, cost reduction, and quality improvement. As technology advances, so do the opportunities to automate complex tasks, resulting in significant productivity gains and the ability to maintain a competitive edge in a rapidly changing market.

The Sandvik whitepaper, developed in collaboration with EY, offers an in-depth analysis of the current state and future of automation in component manufacturing. One of the most striking findings is that 80% of the 350 participating component manufacturers plan to increase their automation levels by 2030.

The study participants, drawn from North America and Europe, highlighted their most significant challenges and enablers in adopting automation. The whitepaper provides valuable insights into how companies of various sizes are navigating these challenges and making strategic investments to enhance their automation capabilities.

According to the whitepaper, several critical enablers are essential for increasing automation levels in manufacturing. These include advanced shop floor equipment, continuous staff training, and real-time data collection. Together, these elements form the backbone of successful automation strategies.

Eric Murander, Head of Business Development and M&A at Sandvik Manufacturing Solutions, emphasizes that while advanced equipment is crucial for the initial steps, the true advancements come from investing in employee training and leveraging real-time data. These investments help manufacturers overcome modern complexities and maintain a competitive edge.

The whitepaper identifies two significant production-related challenges: increased component complexity and a shortage of skilled staff. These challenges can hinder the adoption of automation and impact overall productivity and efficiency.

To address these challenges, the whitepaper suggests a balanced approach that combines automation investments with comprehensive employee training and robust data collection practices. This balanced approach ensures that companies can fully leverage automation technologies and remain competitive in a rapidly evolving market.

For those interested in exploring the detailed findings and recommendations from the Sandvik whitepaper, '6 Levels of Automation in Component Manufacturing,' you can download the full document.

Click below to access this valuable resource. Scroll to the bottom of the page to access the whitepaper download. Stay ahead of the curve by understanding the key trends and strategies in manufacturing automation.

These Stories on 3DCS

No Comments Yet

Let us know what you think