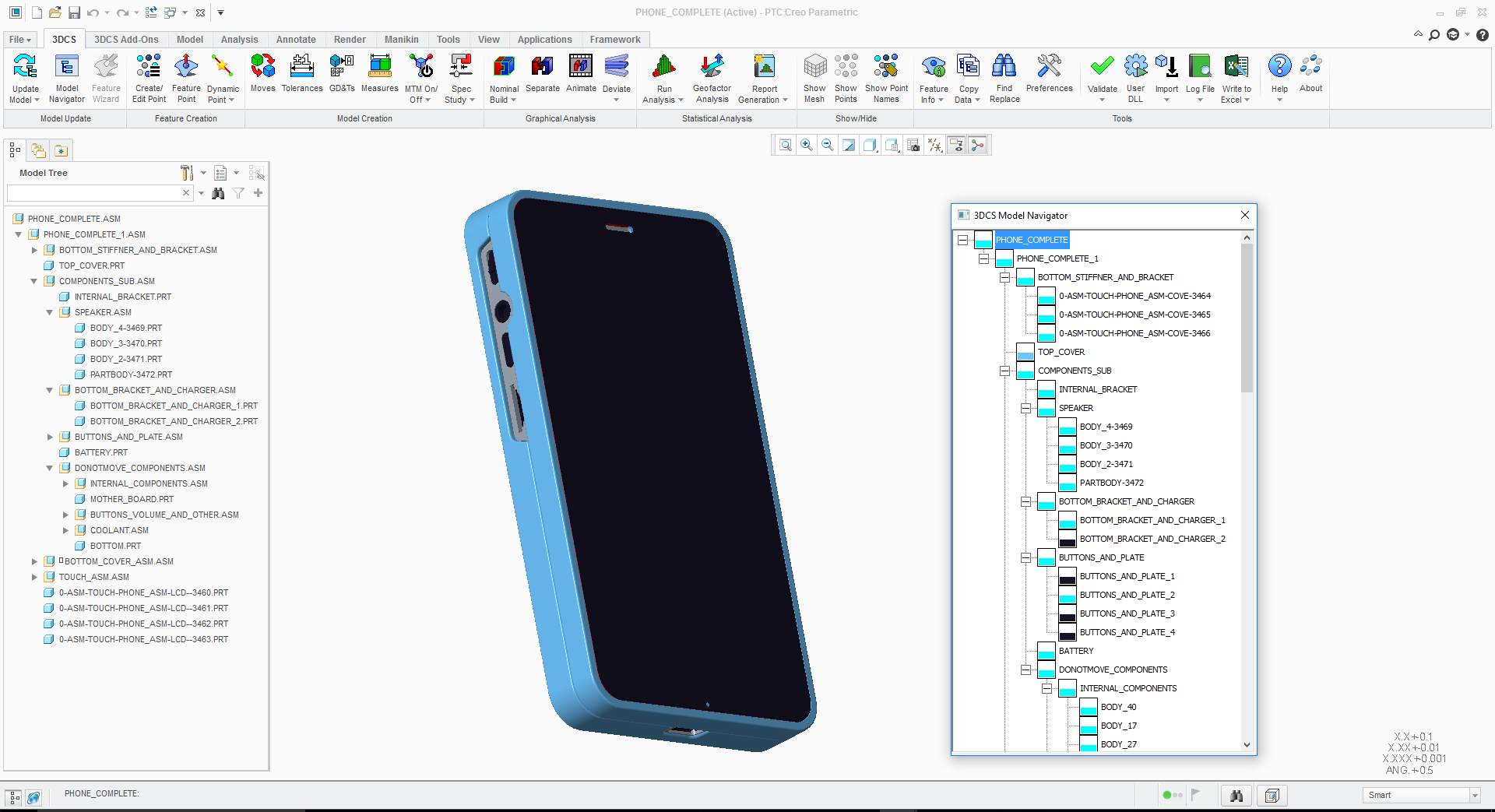

This webinar will showcase 3DCS inside the Creo platform, highlighting moves, tolerances, GD&T and assembly methods.

Your 3DCS model can be stored in the Creo model assembly. This means that where the Creo model goes, so too does the 3DCS model. Where this becomes important is when a PLM system like Windchill becomes involved. Now, whenever you use Windchill to manage your Creo model and version control, you will also be managing your 3DCS model. It also makes it easy to find both your CAD and 3DCS model quickly and continue working or run new analyses.

With 3DCS for Creo you can pull directly from your Creo model. This allows you to apply your GD&T from your Creo model onto your 3DCS model, applying tolerances across your parts. From here, you have the option to simulate and optimize your GD&T.

With 3DCS Mechanical Modeler Add-on, you can pull Joints and Constraints from your Creo model, instantly adding the assembly process to your 3DCS model. analyzing both the part and process information gives you better understanding of your products true variation.

The Creo Assembly Structure stays when you open 3DCS, letting you use it for determining process, and to apply new features. Working both in the CAD and 3DCS makes it easy to make changes and adjustments based on analysis results.

Use features and points from Creo in your 3DCS model to create feature tolerances and moves.

When the Creo model is updated, so is the 3DCS model. Part changes and new design changes can be quickly and easily incorporated into existing 3DCS models to simulate their effect on overall variation.

Keep all of your measurement point the same when bringing your model from Creo into 3DCS, allowing you to easily assemble and place your parts.

%20-%20PTC%20Creo%20Parametric.png?width=750&height=405&name=2017-01-06%2014_13_54-PHONE_COMPLETE%20(Active)%20-%20PTC%20Creo%20Parametric.png)

Register now to get access to the recorded session to share with colleagues

These Stories on 3DCS

No Comments Yet

Let us know what you think