Dimensional Engineering – Datums are Important

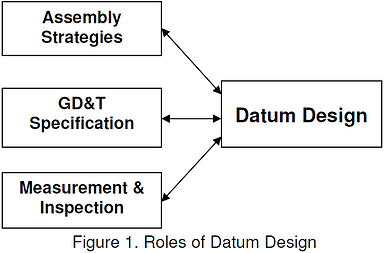

Dimensional Engineering – Datums are ImportantIn a dimensional engineering procedure [Dimensional Engineering News, Dec. 2012], datum design is the second critical task, right behind objective specification. See Figure 1 for an illustration. Datum Design is integral to Assembly Strategies, GD&T (Geometrical Dimensioning and Tolerancing), and Measurement and Inspection Plans.

The definition of a Datum from the Dimensioning and Tolerancing Standard ASME Y14.5-2009 is:

A theoretically exact point, axis, line, plane, or combination thereof derived from the theoretical datum feature simulator.

In other words, Datums have the following characteristics.

(1) Datums are the origins from which the GD&T and Measurements are established.

(2) Datums are derived from actual datum features, not reference points, lines, or planes.

(3) Datums are theoretically exact.

Datums in Assembly

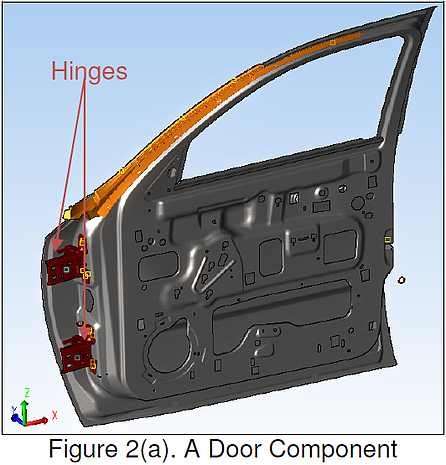

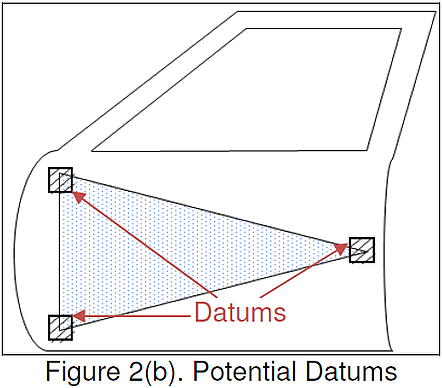

Datums are used to ensure components are assembled as intended. Take a door component as shown in Figure 2(a). Before a door is installed to a car body by the hinges, the door component will be inspected. It is ideal to treat the two hinges as the datums so that the inspection results can directly indicate the assemble-ability, shown in Figure 2(b).

Datums provide common ground between Design and Production for assembly manufacturers.

Why Datums are Important

Datums affect variation

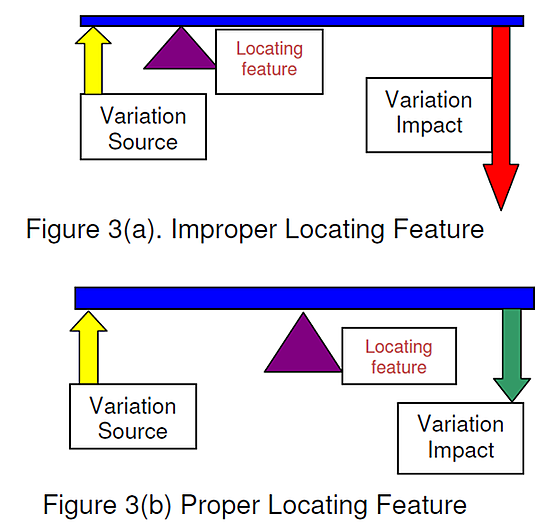

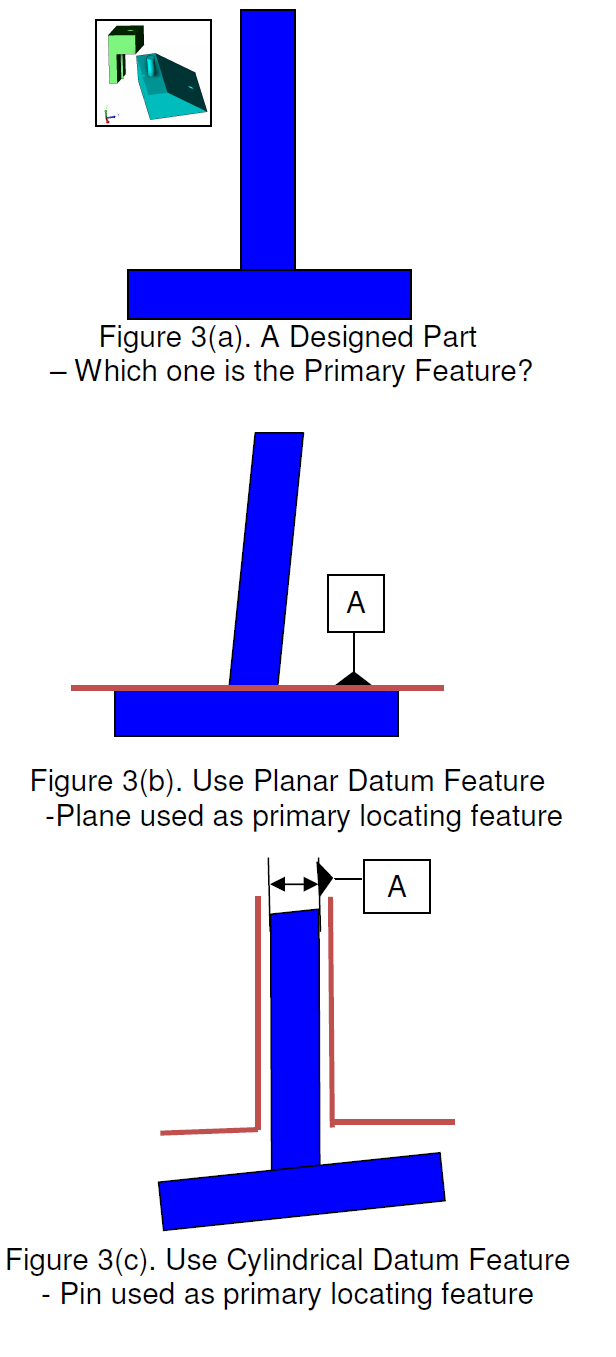

Datums are often used in Assembly Strategies as locating features. Figure 3 (a-b) can be used to illustrate the datum impact on the assembly variation.

It is obvious that the geometrical factor has an impact on the assembly because of the position of locating features.

Why Datums are Important

Datums affect measurements

Datums are also crucial to measurements that affect function. See Figure 3(a-c) for an example. Different assembly alignments will require different datum features.

Get the DE Focus every month by joining DCS's Newsletter

Click here to sign up to receive the DE Newsletter

Editors:

Ying Qing Zhou

Earl Morgan

Victor Monteverde

These Stories on 3DCS

Comments (2)